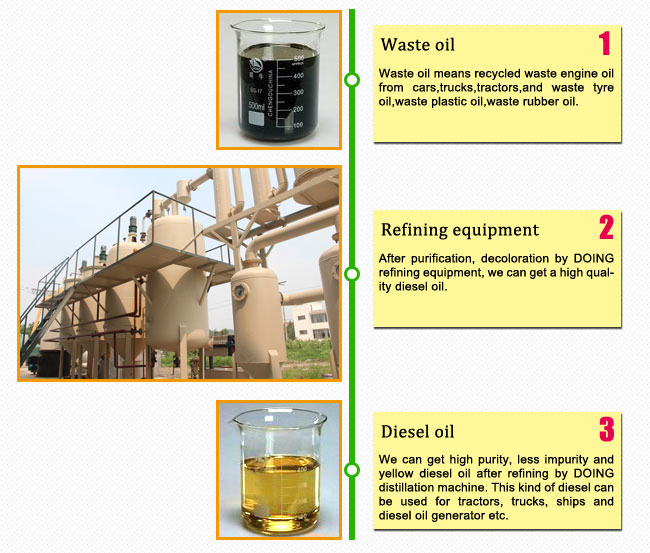

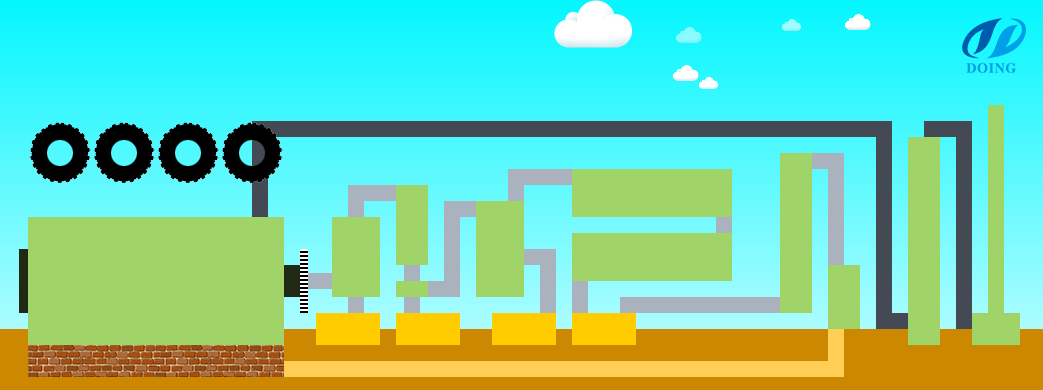

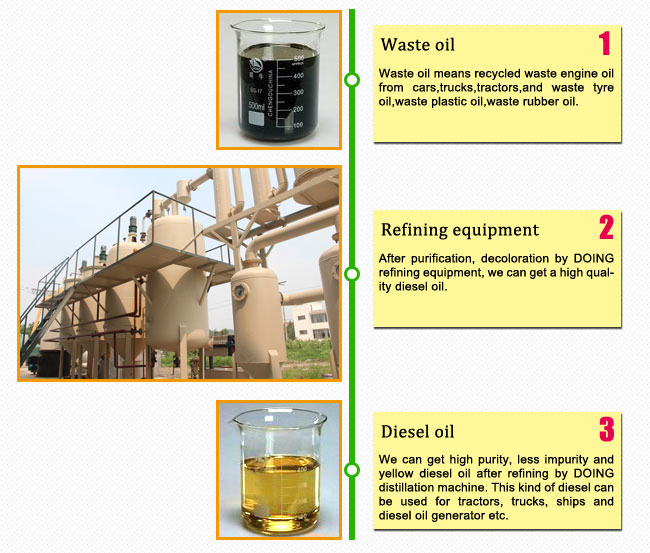

Extracting diesel from waste oil refinery equipment

100% safety assurance:

1. Safety devices such as alarming device, pressure gauge, safety valve. If there is some pressure in the reactor, the alarming device will ring and even no workers hear it, it does not matter as we have the reducing pressure device automatically.

2. Vacuum system can ensure the plant running in a safety condition. Make the whole refining processing be on a normal pressure to avoid accident.

|

Technical parameter of Extracting diesel from waste oil refinery equipment |

|

Items |

Contents |

|

Model |

DY-5t, DY-10t, DY-20t, DY-50t… |

|

Raw material |

Waste engine oil, waste tire crude oil, plastic crude oil |

|

Structure form |

Vertical (easy cleaning and maintenance) |

|

Heating method |

Indirect heating to prolong the machine service life |

|

Operating pressure |

Constant pressure |

|

Heating material |

Coal, charcoal, fuel gas, fuel oil |

|

Average out-put oil rate |

95% |

|

Material of reactor |

4 reactor with different material |

|

Thickness of reactor |

18mm |

|

Mode of cooling |

Recycled water cooling |

|

Power in total |

20 Kw |

|

Service life |

average 7 years |

|

Land area |

180㎡ |

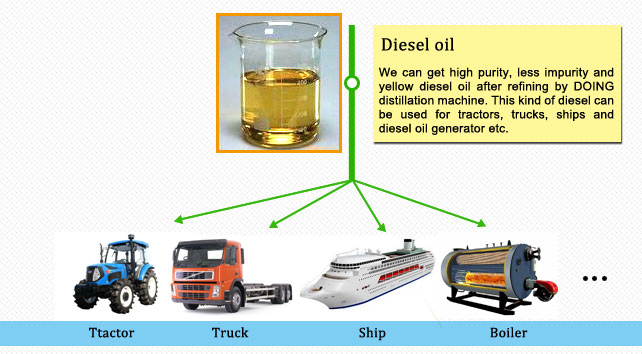

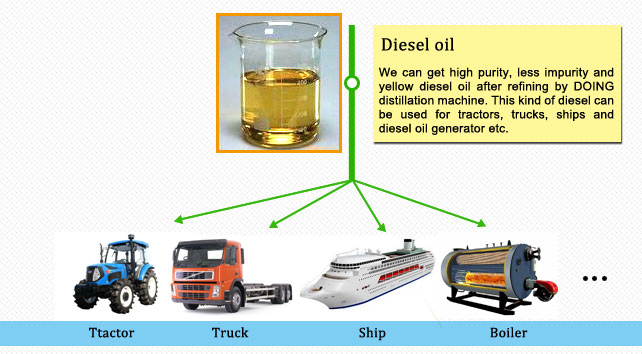

Waste oil refinery equipment applied for waste engine recycler, waste oil collect center and also used by who have lots of waste tyres and plastic. The final diesel after refining can be used for tractors, trucks, ships and diesel oil generators etc. below is the different waste oil with its oil rate.

|

Oil yield of different material: |

|

No. |

Name |

Oil yield |

|

1 |

Waste tire oil |

85%-90% |

|

2 |

Waste plastic oil |

95% |

|

3 |

Waste engine oil |

85%-90% |