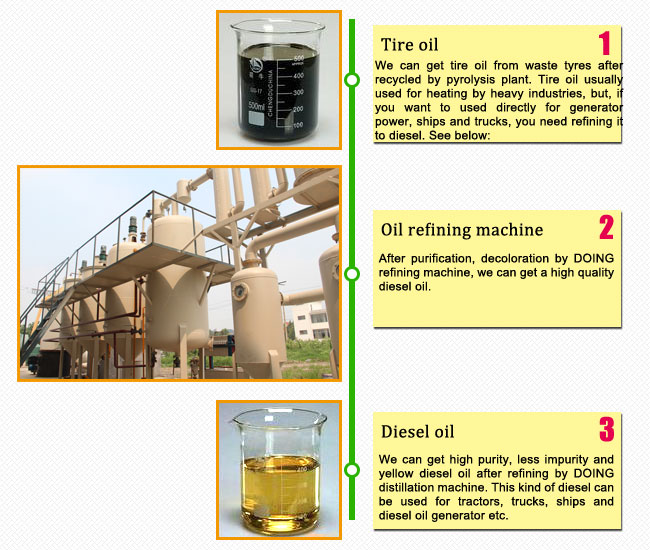

As we know we can get tire oil from waste tire by pyrolysis plant, but, it seems lots of people want to get high quality diesel oil. Then, the tire oil to diesel become a very hot and highly profitable green project, which is low cost, easy to collect the raw material and can convert waste tyre oil to diesel (oil recovery rate is about 80%-90%) Why more and more people are willing to invest this new project? As we all known, with the car industry increasing, the number of waste tyres in the world increases sharply. At the same time, oil resources are decreasing every day. How to dispose of waste tyres and related problems?

Chat Online Leave A Message

| Technical parameter of Tire oil to diesel refining machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | Waste engine oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |