Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

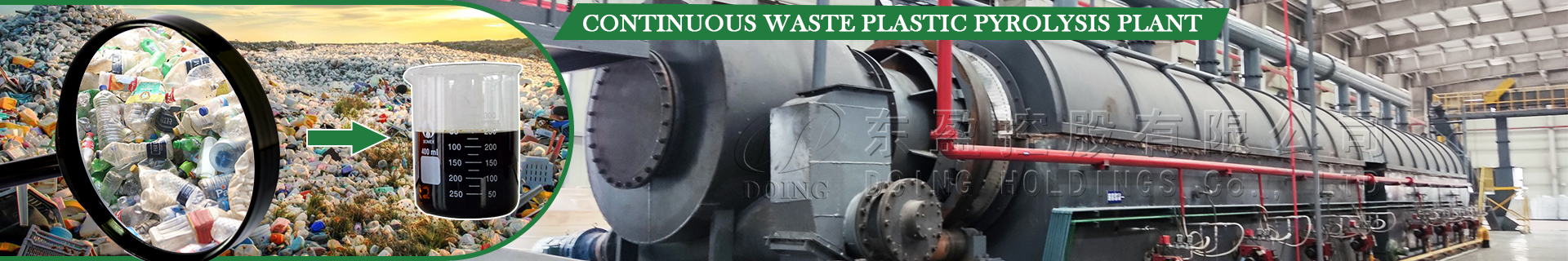

Continuous waste plastic pyrolysis plant

Continuous type waste plastic pyrolysis plant supplier includes waste plastic pretreatment systm,continuous pyrolysis sy...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Henan Doing produce continuous type waste plastic pyrolysis plant not only can solve the problem,but also can bring hugh profit for you!

Continuous waste plastic pyrolysis plant

- Features:

- Technical Data:

- Application:

Continuous type waste plastic pyrolysis plant supplier

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

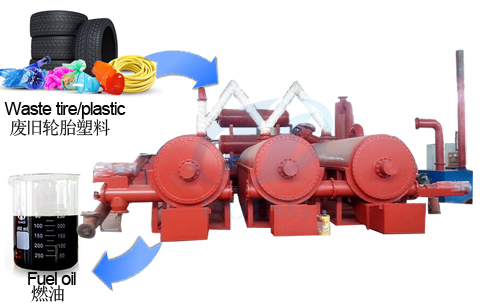

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

Continuous waste plastic pyrolysis plant is a very good investment, not only can efficiently deal with a large number of abandoned plastic, turn waste into treasure, but also can avoid environmental pollution caused by landfill or burning these waste.

Final product applicatin of continuous waste plastic pyrolysis plant:

1. Fuel oil

Fuel oil can directly used for boiler heating, cement plants, steel plants, glass plants, etc. Besides, fuel oil can also be refined by waste oil distillation machine into diesel,which can be used as alternative diesel for diesel burners,agricultural machinery, etc.

2. Carbon black

Carbon can be used for industrial heating by pressing ball combustion, its combustion calorific value is equivalent to that of coal, or be refined into different standards, used as additives for paints, pigments, rubber products, etc.

3. Uncondensable gas

The uncondensable gas can be recycled to heat pyrolysis reactor to save fuel or collected for other heating use.

Application of end products of waste plastic pyrolysis plant

Application of end products of waste plastic pyrolysis plant

Doing Group continuous waste plastic pyrolysis plant can not only process waste plastic, but also waste tires, the capacity is between 20T and 50T, the oil yield can recah 45%. Foe more information about continuous waste tplastic pyrolysis plant, welcome to consult us.

Previous: Continuous scrap plastic pyrolysis plant

Next: Nothing

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.