Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Continuous process tire pyrolysis plant

The continuous process tire pyrolysis plant is a PLC control system that can realize continuous feeding, continuous disc...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Continuous process tire pyrolysis plant

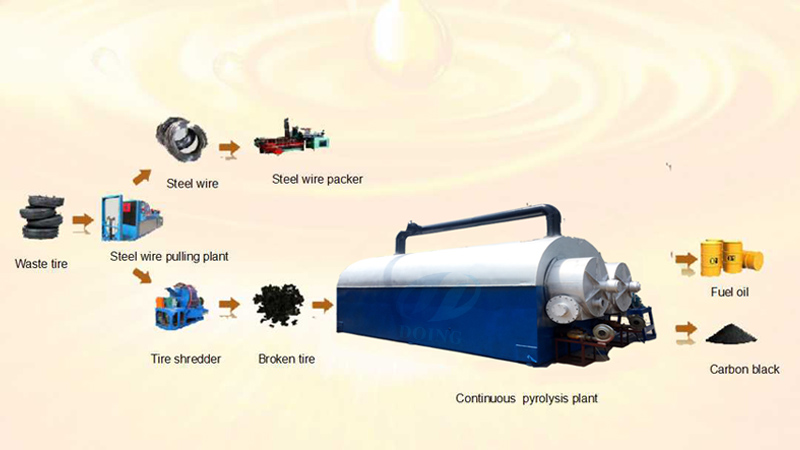

Continuous process tire pyrolysis plant working process

1. Withdraw the collected tires with a wire drawing machine.

2. Put the wire pulling tire into the tire crusher and break the tire into small pieces of 3-5cm.

3. Put the tire scrap into the continuous process tire pyrolysis plant and heat the reactor. After much and pyrolysis reaction and condensation finally get fuel.

4. The end of equipment operation will be automatically discharged carbon black.

Continuous process tire pyrolysis plant

1. Relative to the intermittent tire cracking equipment, the single machine processing capacity is large and the floor space is small.

2. Use PLC control system to save manpower.

3. An accurate calculation system ensures that the waste tire can be fully cracked and the oil yield is high.

4. The pyrolysis reactor adopts an internal rotation device and does not need to periodically stop the replacement of the sealing material.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

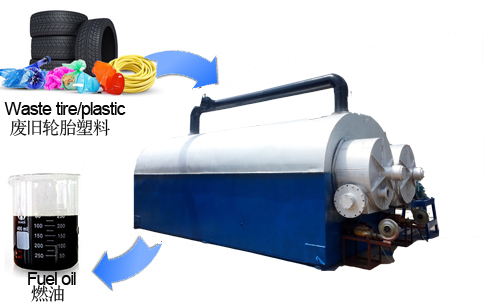

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

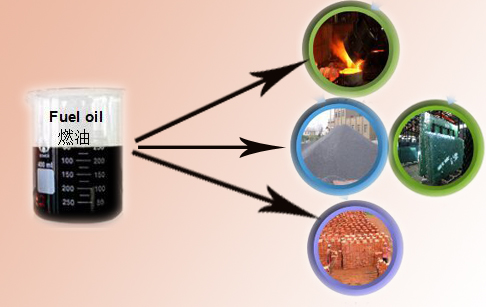

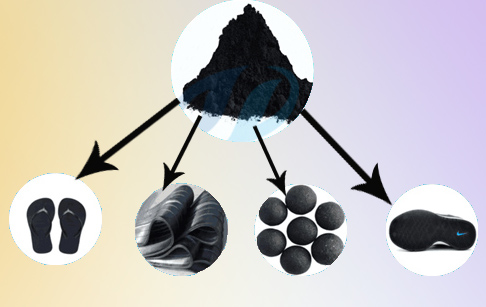

Fuel oil usage

Carbon black usage

3. Steel wire: Mainly used for waste recycling and recasting.

4. Combustible gas: It will be recycled by the equipment and reused in the heating fuel of the reactor.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.