Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Advantages of continuous waste tire pyrolysis plant

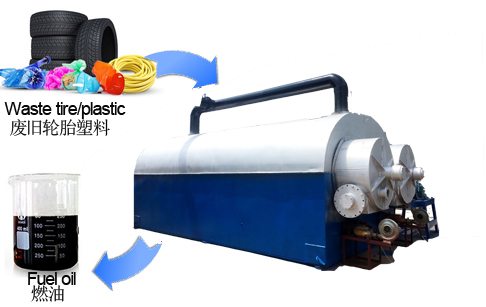

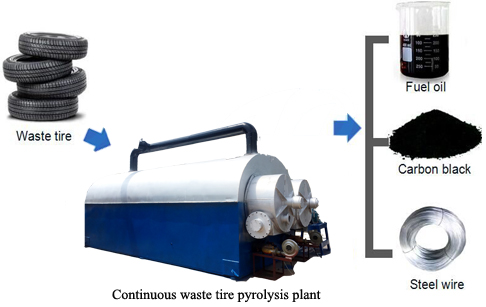

Continuous waste tire pyrolysis plant is the equipment line which can process waste tires to fuel oil, carbon black and ...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Continuous waste tire pyrolysis plant

As the vehicle increasing with the improving living standard, more and more waste tires generated every day. And waste tires as a solid waste not only occupy the land, the most important is it cause pollution to the environment. So how to dispose the waste tires becoming more and more necessary. That’s why we developed the continuous waste tire pyrolysis plant.

Advantages of continuous waste tire pyrolysis plant

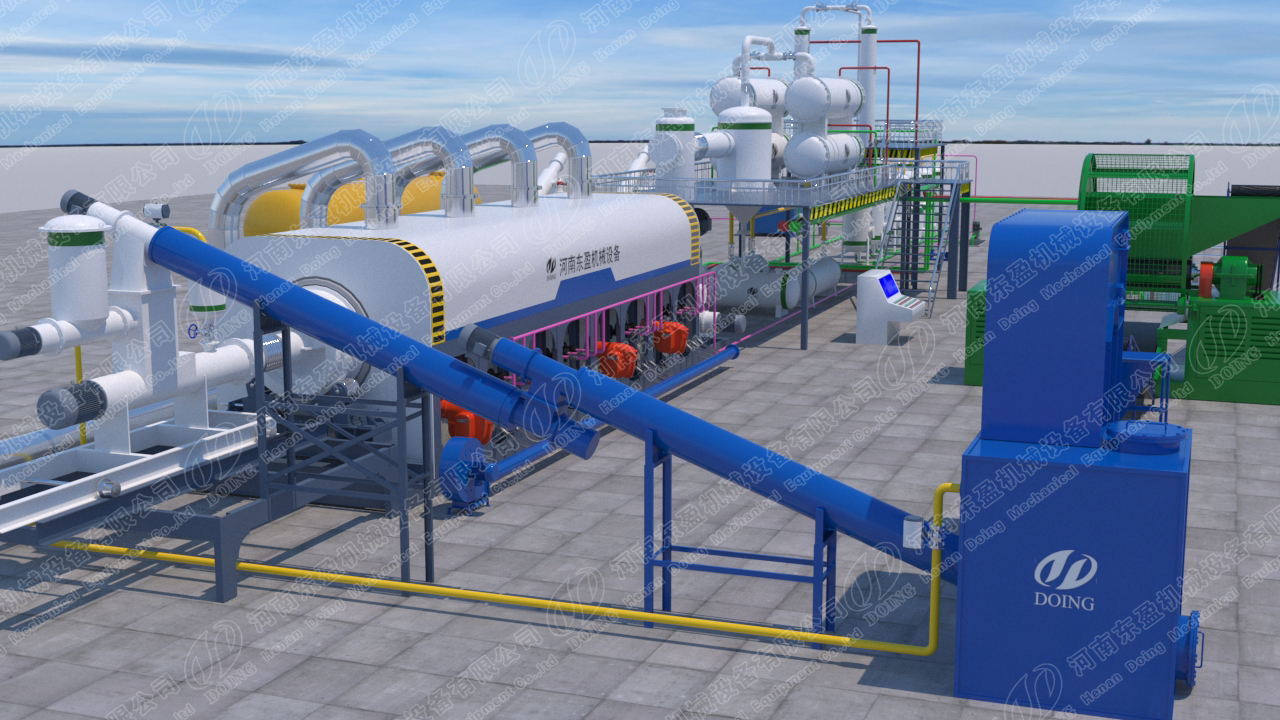

Continuous waste tire pyrolysis plant working process

Advantages of continuous waste tire pyrolysis plant

Continous waste tire pyrolysis plant

1.High capacity, which can process at least 10 tons waste tires per day, up to 100 tons waste tires per day;

2.Fully automatic with continuous feeding and discharge system;

3.PLC or computer control system, thus to save labour;

4.Multiple reactors design for fully pyrolysis to get high oil rate;

5.Indirect heating to prolong the usage life of the reactor;

6.Same as the batch type pyrolysis plant, it’s also applicable to process waste plastics.

If you want to know more informations about our continuous waste tire pyrolysis plant, please feel free to contact us. We DONG Company has specialized in waste tire pyrolysis project for about 8 years, we would like to provide valuable informations and suggestions to help you implement this project.

- Features:

- Technical Data:

- Application:

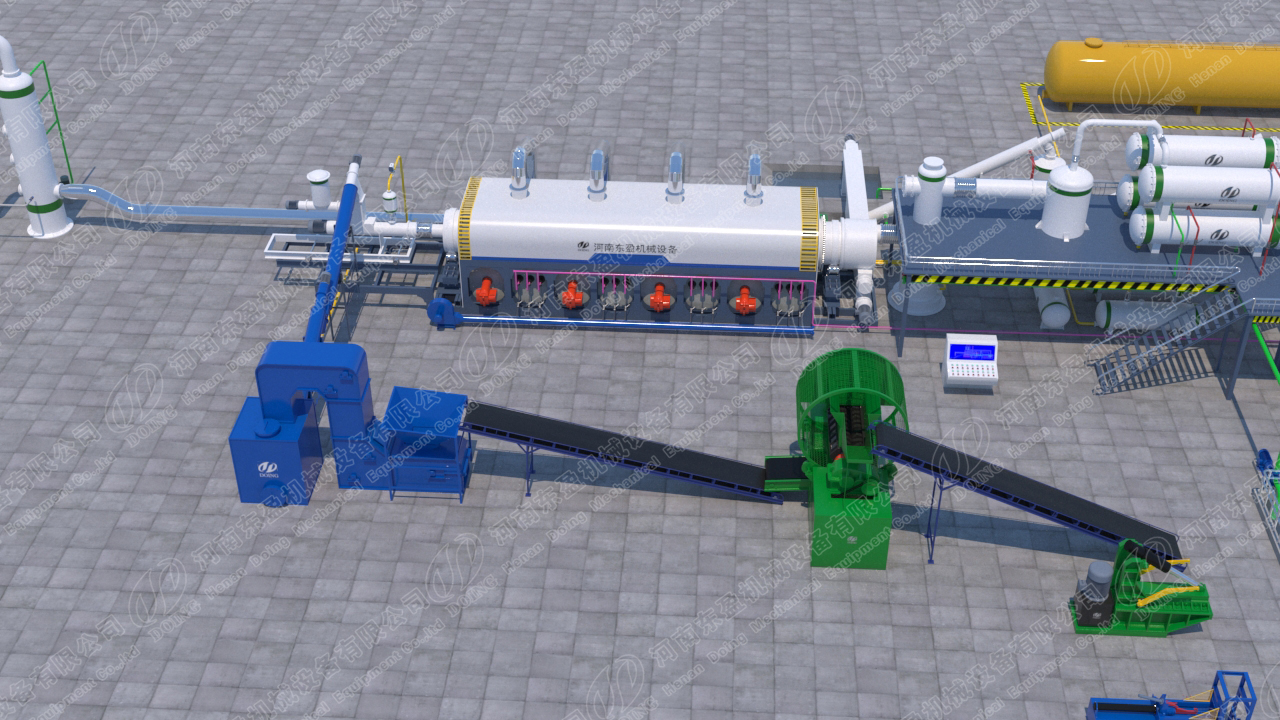

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

Fuel oil application

| Yield | Application | |

| Tire oil | 50% | 1. Sold outward. |

| 2. Added into heavy oil generator to produce electricity. | ||

| 3. Transformed into diesel or gasoline by oil distillation equipment. | ||

| 4. As fuel to heat the reactor. | ||

| Carbon black | 30% | 1. Sold outward. |

| 2. Reprocessed into color master batch. | ||

| 3. Reprocessed into coal or refractory briquette. | ||

| Steal wire | 12% | 1. Sold outward. |

| 2. Deep processed into steal bloom by hydraulic press-packing. | ||

| Combustible gas | 8% | 1. Back to furnace for heating the reactor. |

| 2. Stored as fuel for heating. |

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.