Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING DY-15 Waste Tire Pyrolysis Machine Project Successfully Installed in Kenya

-

DOING 45,000 Tons/Year Waste Plastic Pyrolysis Project in Vietnam Successfully Commissioned

-

DOING Tire & Plastic Pyrolysis Distillation Plant Successfully Installed in Fiji

-

DOING 50TPD Continuous Oil Sludge Pyrolysis Production Line Successfully Installed in China

-

DOING Installed 15-Ton Tank Bottom Sludge Pyrolysis Equipment for Colombian Repeat Client

-

DOING 30TPD Mazut Oil Distillation Plant Successfully Installed in Kazakhstan

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

How are automobile tyres recycled into oil?

2022-07-05 / Continuous Pyrolysis plant / Leave Message / Chat Online

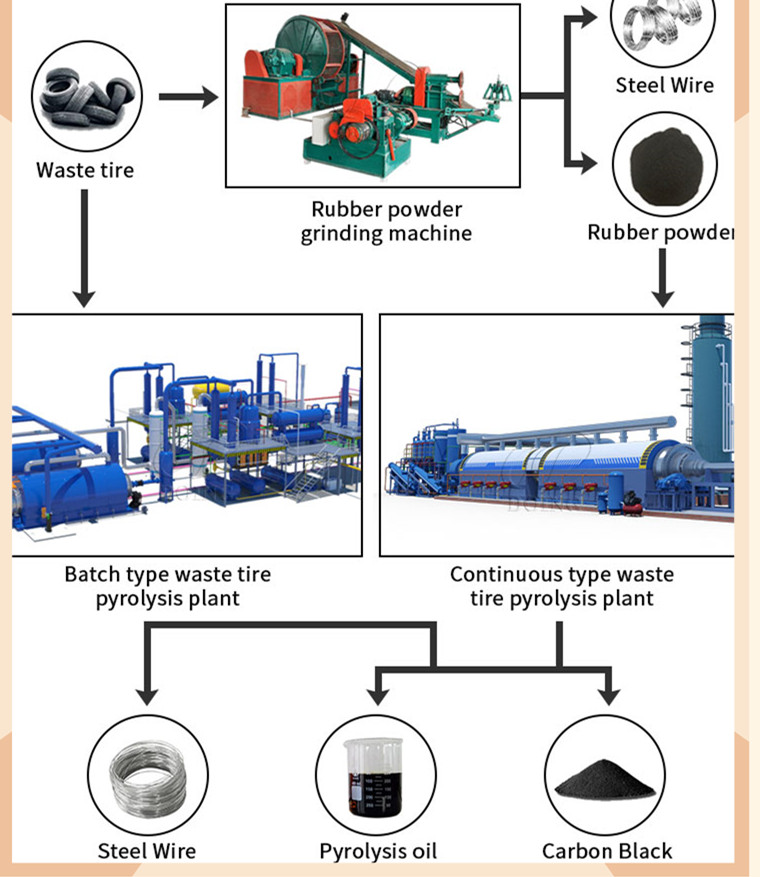

Recycling automobile tyres into oil is a popular investment project in recent years. It can not only realize the reuse of automobile tyres, but also earn good economic benefits. Recycling automobile tyres into oil requires the use of batch/automatic waste tyres pyrolysis plant to make automobile tyres undergo a cracking reaction inside.

The pyrolysis reaction is the process of converting high molecular compounds into several low molecular compounds through high temperature heating. And the automobile tyres can be recycled into fuel oil, non-condensable gas, steel wire and carbon black.

The detailed processes of recycling automobile tyres into oil are as follows:

The process of waste tyre recycling to fuel oil plant

The process of waste tyre recycling to fuel oil plant

1.Pre-treatment:

If you want to speed up the cracking efficiency, it is generally recommended to draw the steel wire out and pulverize the automobile tyres first. The steel wire obtained from it can be directly sold to obtain economic benefits.

2.Cracking

Then use a screw conveyor to feed the finely crushed automobile tyres to the waste tyres pyrolysis plant reactor for heating, and a high-temperature pyrolysis reaction occurs.

3. Condensation

The oil gas generated by the cracking of automobile tyres will be buffered by the buffer tank, and then enter the condensation system for further condensation. After condensation, more fuel oil is obtained into the oil tank.

4. Purification

During the whole process of high-temperature heating to obtain pyrolysis oil, some flue gas will be generated, which will be purified by the desulfurization tower and finally discharged to the EIA standard.

5. Slag discharge

The carbon black obtained from the automobile tyres pyrolysis process will be discharged through the carbon black slag discharge device (screw elevator, wind transfer system).

Henan Doing Company has been engaged in R&D and manufacturing of waste tyres pyrolysis plants for 11+ years. At present, we have developed two machines to recycle automobile tyres into oil for customers to choose, batch waste tyres pyrolysis plant and continuous waste tyres pyrolysis plant. You can choose the most suitable one according to your actual investment scale. For more detailed information on waste tyres pyrolysis plants, please call for consultation.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.