Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

How much does a continuous pyrolysis plant cost?

2022-06-28 / Continuous Pyrolysis plant / Leave Message / Chat Online

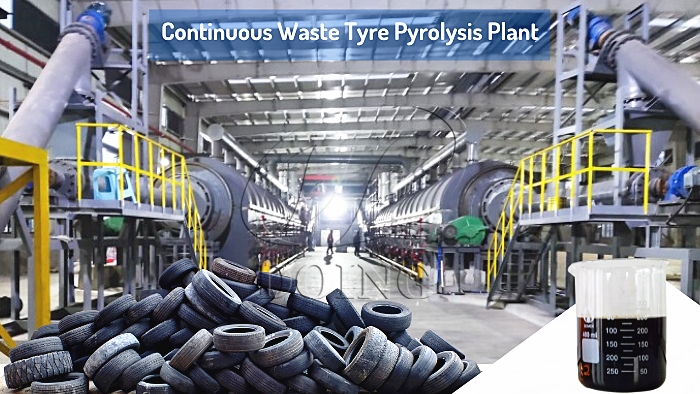

Continuous pyrolysis plant technology has become a new trend of many waste rubber tires/plastic pyrolysis and recycling projects because of its high degree of automation, large processing capacity, energy and labor saving. So how much is a set of this continuous pyrolysis plant? In fact, the continuous pyrolysis plant costs vary from $300,000-$700,000 per set.

The continuous pyrolysis plant costs vary a lot because different machine capacities and machine configurations get different prices.

Firstly, you need to confirm how many tons of daily capacity you want. Now our Doing Company has continuous pyrolysis plants with 15/20/30/50/70 tons daily capacities for your choice. The bigger capacity you choose, the more profits you could get, relatively the machine cost is more competitive. Take the continuous pyrolysis plant with 50 tons daily capacity DOING usually installed for our customers, and the price of it is from $495,000 to $700,000.

Then you need to confirm which level of standard environmental protection you want to match up with. We have different environmental protection device configurations to choose, so as to help customers to promote the smooth operation of the continuous pyrolysis project with the permission of the local government, while saving investment costs.

Fully continuous waste tyre pyrolysis project cases

Fully continuous waste tyre pyrolysis project cases

You can tell us your detailed needs, and our dedicated manager could give you suggestions according to your budget, to design the plan of continuous pyrolysis plant for you step by step. Till now, our DOING continuous pyrolysis plants have been exported to many countries, such as Kazakhstan, Brazil, Russia, Italy, Thailand, etc. And they are well received by our customers at home and abroad.

Here are some advantages of our continuous pyrolysis plant, welcome to inquiry us for free quote!

1.High oil yield

New technology continuous pyrolysis plant has perfect cooling system which is improved based on the old technology. It can ensure all the oil gas can be cooled and converted into fuel oil.

The advantages of fully continuous pyrolysis plant

The advantages of fully continuous pyrolysis plant

2.Environmental friendly

Professional dedusting system will effectively process possible pollution in the smoke, thus avoiding zero pollution to the air. Exhaust gas recycling system can recycle waste gas for heating directly, which is environmentally friendly and can save energy during the process of continuous pyrolysis process.

3.Safe

We have a strict quality control system on each step production of our continuous pyrolysis plant, which will guarantee the machine life and safety.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.