Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

What’s the working principle of waste tire pyrolysis plant?

2021-08-26 / Continuous Pyrolysis plant / Leave Message / Chat Online

Doing Group waste tire pyrolysis plant adopts pyrolysis technology to pyrolyze waste tires into fuel, carbon black, steel wire and uncondensable gas. Pyrolysis refers to the process of converting high molecular compounds into low molecular compounds in the absence of oxygen at high temperature. Therefore, the working principle of waste tire pyrolysis plant is pyrolysis. Then, what's the working process of waste tire pyrolysis plant?

The main working process of Doing Group waste tire pyrolysis plant includes feeding, high temperature pyrolysis, cooling oil gas, tail gas treatment, smoke cleaning, and carbon black collection. The following is the specific working process of Doing Group waste tire pyrolysis plant.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

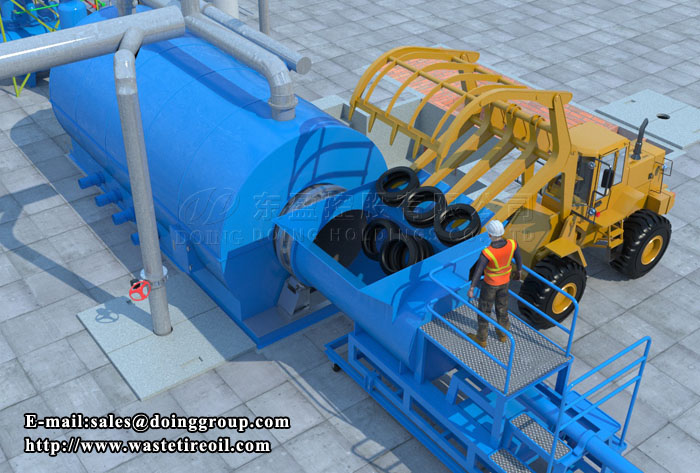

1. Feeding.

Sending waste tires into the pyrolysis reactor, the batch pyrolysis plant adopts manual feeding, and the continuous pyrolysis plant adopts the automatic feeder. At present, the most commonly used is the automatic feeder,which has the advantages of high production efficiency, saving manpower, shortening the entire system time, and safety.

Batch waste tire pyrolysis plant feeding

Batch waste tire pyrolysis plant feeding

2. High temperature pyrolysis .

After heating the pyrolysis reactor to 100°C, the moisture and small molecules in the tire will evaporate. When the temperature rises to 140°C, the tire begins to melt into a liquid. After the temperature in the reactor reaches 260°C, oil gas will be generated. Keep it for 6-10 hours (depending on the actual situation) until tire is completely vaporized. The oil gas obtained by pyrolysis will be cooled in the cooling system.

Heating pyrolysis reactor

Heating pyrolysis reactor

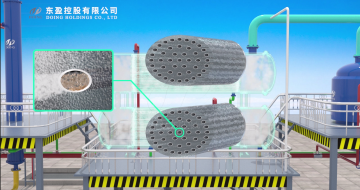

3. Cooling oil gas.

The oil gas produced by pyrolysis first pass through the buffer tank to slow down the flow rate of the oil gas, and then pass through the four-stage cooling system to cool down into fuel oil. The fuel oil is stored in three temporary storage tanks with different purity levels.

Horizontal condender

Horizontal condender

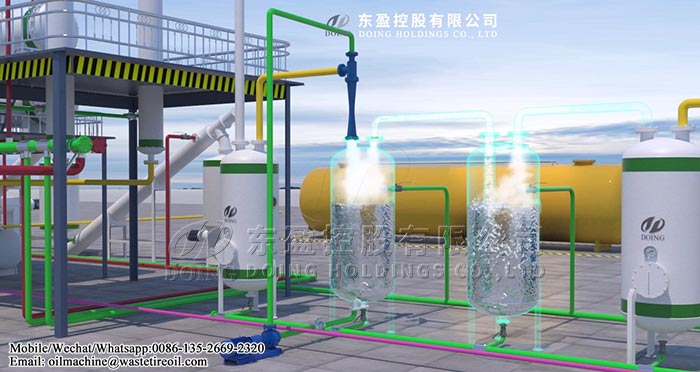

4. Tail gas treatment.

Part of the uncondensable but combustible tail gas in the cooling systemcan be treated by the tail gas cleaning system, and then collected by the industrial pressure vessel to heat the pyrolysis reactor to save fuel and no waste.

Tail gas cleaning system

Tail gas cleaning system

5. Smoke cleaning.

The smoke generated during the fuel combustion process can remove harmful substances such as sulfur after being processed by the smoke cleaning system, and can meet the national gas emission standards without causing secondary pollution to the environment.

Smoke cleaning system

Smoke cleaning system

5. Carbon black and steel wire collection.

The carbon black is discharged and collected by a sealed screw elevator. After the pyrolysis reaction is over, wait until the temperature of the pyrolysis reactor drops to 40 degrees, and then the remaining steel wire can be taken out.

Carbon black wind transport system

Carbon black wind transport system

The above is the whole working principle and process of Doing Group waste tire pyrolysis plant. Besides, we also provide 3D animation videos for your reference. If you want to know more about waste tire pyrolysis plant, please feel free to contact us.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.