Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Is there pollution in the working process of waste tire pyrolysis plant?

2021-08-26 / Continuous Pyrolysis plant / Leave Message / Chat Online

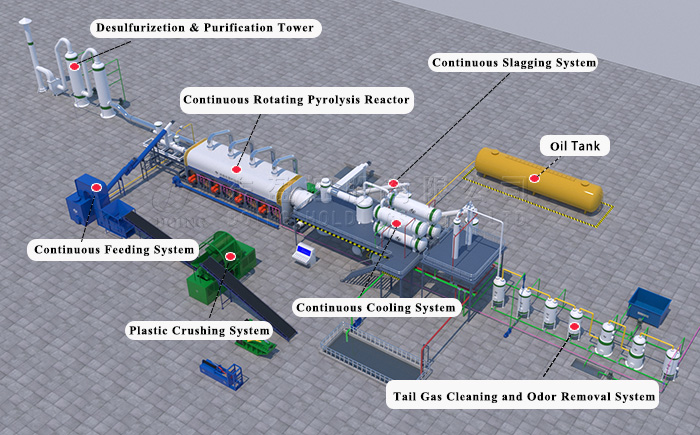

The working process of the waste tire pyrolysis plant will produce gas pollution, there are tail gas and smoke. In order to deal with gas pollution, Henan Doing Waste Tire Pyrolysis Plant is equipped with a complete environmental protection system, including tail gas cleaning system and smoke cleaning system. After being treated by the environmental protection system, the exhaust gas can meet the national gas emission standards and will not cause secondary pollution to the environment. Therefore, there is no pollution in the working process of Henan Doing waste tire pyrolysis plant. Next, let's take a look at how Henan Doing Waste Tire Pyrolysis Plant deals with gas pollution.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

1. Tail gas treatment.

The waste tire will produce oil gas during the heating process, then the oil gas are cooled into fuel oil through the cooling system. Part of the uncondensable but combustible gas is called tail gas, which contains a component of hydrogen sulfide, which is an inorganic compound. Under standard conditions, it is a colorless and flammable acid gas. At low concentrations, it has the smell of rotten eggs and the taste is unpleasant. Henan Doing Waste Tire Pyrolysis Plant is equipped with tail gas cleaning system to remove hydrogen sulfide. The treated tail gas can be collected and used to heat the pyrolysis reactor without causing pollution to the environment.

Tail gas cleaning system

Tail gas cleaning system

2. Smoke treatment.

In the process of fuel combustion, smoke is generated. The smoke mainly contains sulfur dioxide, nitrogen oxides, other particulate matter, etc. The country has emission standards for these smoke. The smoke cleaning system of Henan Doing Waste Tire Pyrolysis Plant uses chemical methods to remove these harmful and unpleasant substances. The treated smoke meets the gas emission standards and can be discharged into the air.

Smoke cleaning system

Smoke cleaning system

Henan Doing waste tire pyrolysis plant has passed the European and American environmental standards and we have installed many equipment in more than 90 countries around the world. If you are interested in environment-friendly waste tire pyrolysis plants, please contact us, our engineers will provide suitable solutions for you.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.