Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Is pyrolysis plant harmful to the environment?

2021-08-26 / Continuous Pyrolysis plant / Leave Message / Chat Online

In the past, some waste tire pyrolysis plant did not meet the environmental protection requirements, causing serious harm to the environment, especially soil and water pollution. However,the current environmentally friendly waste tire pyrolysis plant not only achieves the purpose of recycling waste materials, but also does not pollute the environment during the production process. Doing has been doing waste tire pyrolysis for more than ten years and has rich experience. Now I will give you a detailed analysis.

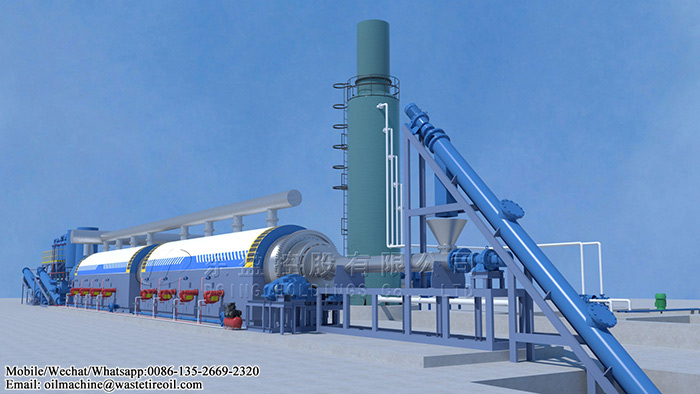

Waste tire pyrolysis plant

Waste tire pyrolysis plant

The pollution of industrial production to the environment is mainly reflected in the aspects of waste water, waste gas and dust. Doing's waste tire pyrolysis plant has achieved good prevention and control in these aspects.

1. Waste water pollution control

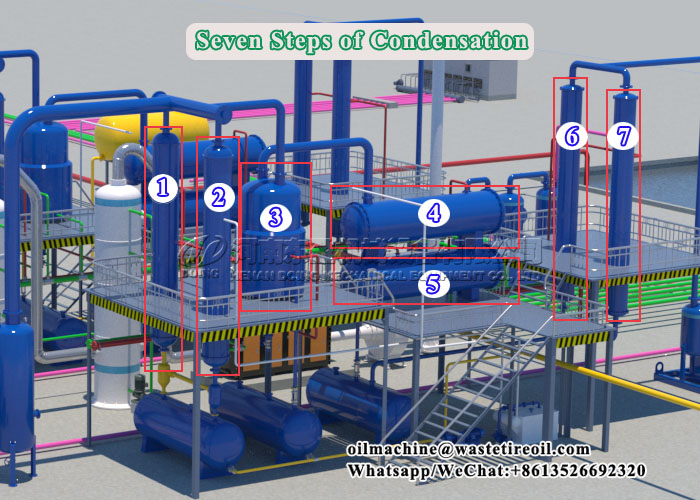

After high temperature pyrolysis, waste tires need to be condensed into oil. Our condensing system adopts a tube-and-tube condenser design with oil inside the tube and water outside the tube. There is zero contact between water and oil, and the cooling water can be recycled without discharge. It is environmentally friendly and increases the cooling area to ensure zero discharge of wastewater during the production process.

Cooling system

Cooling system

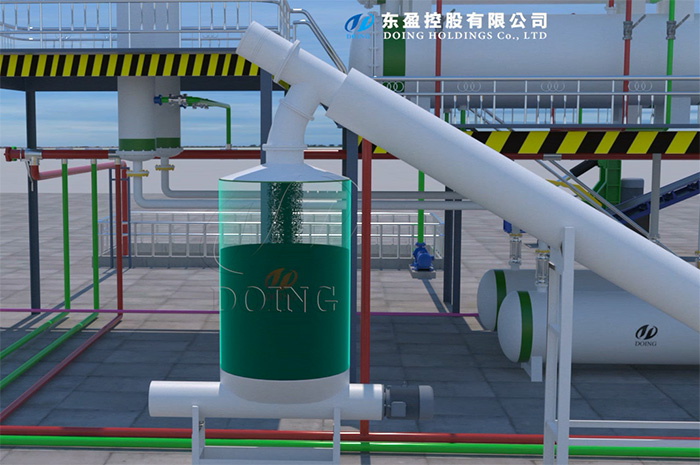

2. Waste gas pollution control

In the disposal of waste gas, Doing company is equipped with a deodorization system and a desulfurization tower. The non-condensable gas passes through the deodorizing system and enters the combustion chamber of the cracking furnace to be burned as fuel, which is environmentally friendly and saves fuel. When the fuel is burned to heat the reactor, some smoke will be produced, which contains harmful substances. If it is discharged directly, it will cause air pollution. After filtering through the desulfurization tower, it can meet the environmental protection standards of developing and underdeveloped countries.

Deodorization system and a desulfurization tower

Deodorization system and a desulfurization tower

3. Dust pollution control

Thermal pyrolysis of waste tires will not only generate oil, but also carbon black and steel wire. If the carbon black is not handled properly, it will cause dust pollution. Doing uses wind power to transport the carbon black through a fully enclosed pipeline. And then use the carbon black trap to collect it centrally. At the same time, the carbon black air transportation system is equipped with pulse bag dust removal. In this way, the carbon black can be collected to minimize the dust pollution caused by the carbon black to the production workshop and the surrounding environment.

Carbon black through the fully enclosed pipeline

Carbon black through the fully enclosed pipeline

To sum up, you don’t need to worry about whether waste tire pyrolysis plant will pollute the environment anymore. The current waste tire pyrolysis has done a good job in environmental protection. If you want to do the waste tire pyrolysis business, the environmental protection specifications of your country is relatively high, you can contact us, our salesman can make the best plan according to your situation.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.