Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

Can waste plastic turn into fuel?

2021-08-13 / Continuous Pyrolysis plant / Leave Message / Chat Online

The answer is yes. Waste plastics can turn into fuel to produce pyrolysis oil and carbon black through waste plastic pyrolysis plant. Pyrolysis oil is a new type of fuel with a wide range of uses and low pollution. Carbon black can also be briquetted for burning. This method can not only recycle waste plastics, but also produce energy and turn waste into treasure.

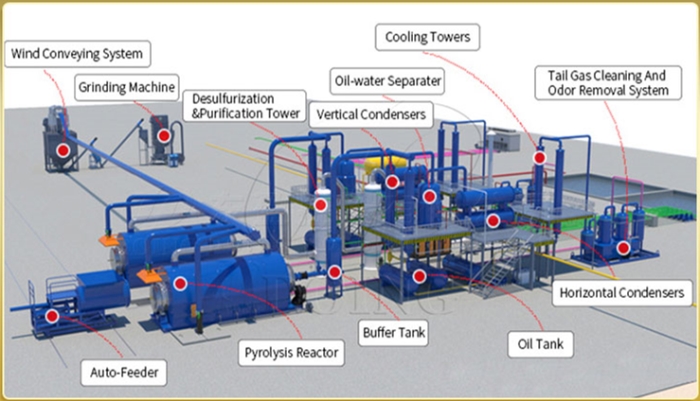

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

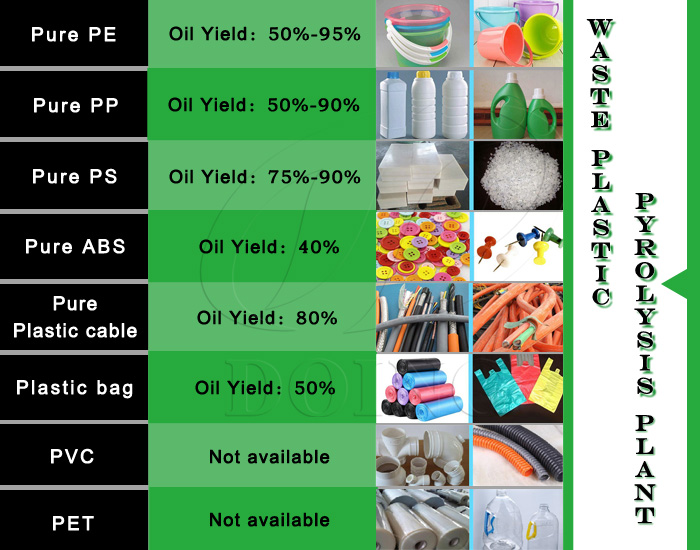

The common plastics in our lives can be pyrolyzed. For example, pure PP plastic, pure PE plastic, pure PS plastic, pure ABS plastic and domestic plastic garbage. Different plastics have different oil yields.

The matetials for waste plastic pyrolysis plant

The matetials for waste plastic pyrolysis plant

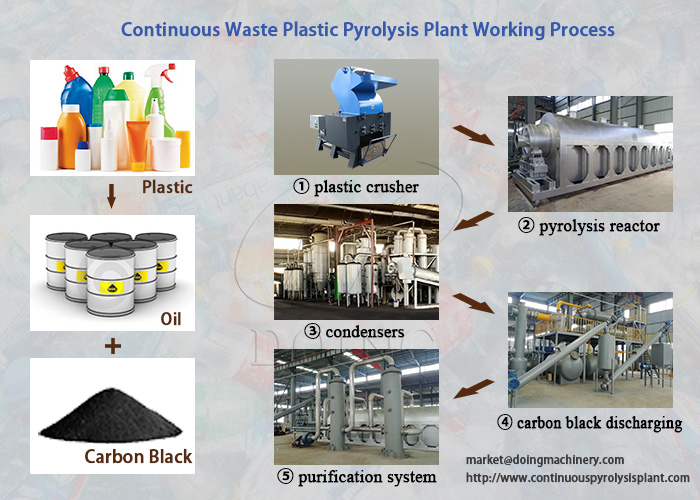

Let's take a look at how waste plastic turn into pyrolysis oil and carbon black.

1. Feed waste plastic

Feed the waste plastic into the reactor through the automatic feeder. It takes about 2 hours. According to the water content of the plastic, there are two methods: Dry plastic, which can be directly fed. Close the door and heat directly after it is full; Wet plastics need to be heated while feeding.

2. High temperature pyrolysis

Heating the waste plastic in the reactor for about 4-5 hours, about 1 hour will produce oil and gas.

3. Condensed into oil

After passing the condensing system, the oil and gas are condensed into oil.

4. Recycle exhaust gas

In the process of heating waste plastic to make oil, in addition to oil and gas, some combustible but non-condensable gas will also be produced. This gas can be directly recycled to save fuel.

5. Discharge the carbon black

After the waste plastic oil production process is over, the oil and gas is exhausted. The residual material in the reactor needs to be discharged to carry out a new oil production process. This residual material is mainly carbon black.

Workflow of waste plastic pyrolysis plant

Workflow of waste plastic pyrolysis plant

Turning waste plastic into fuel requires high quality machine. If the quality of the pyrolysis oil is not up to the standard, there is no way to meet the market demand. Doing's waste plastic pyrolysis plant adopts advanced technology, which not only has high oil yield, but also is safe and environmentally friendly. If you want to know more details, you can contact us at any time.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.