Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Video

-

PLC control fully continuous pyrolysis technology 3D working video

-

14Ton waste oil recycling machine in Indonesia operation site

-

Fully continuous tire pyrolysis plant working process 1: waste tire pre-treatment

-

Semi-continuous tire pyrolysis machine process flow 3D video

-

Waste Oil Sludge Thermal Decomposition Units(TDU) Running Site Live Video

-

50TPD fully continuous tyre pyrolysis plant in India display video

-

Three types of DOING waste tire pyrolysis plants real shot display video

-

Fully continuous waste tire pyrolysis plant project installed by DOING introduction video

-

-

12 sets of 12tpd waste tire pyrolysis plants installed in China video

Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

Continuous waste tyre pyrolysis plant running process video

2022-01-18 / Video / Get Price / Chat Online

This is the video of the display and running process of the continuous waste tyre pyrolysis plant. The purpose of publishing the video is to help customers better understand the components and actual running process of continuous waste tyre pyrolysis plant. The whole process looks spectacular.

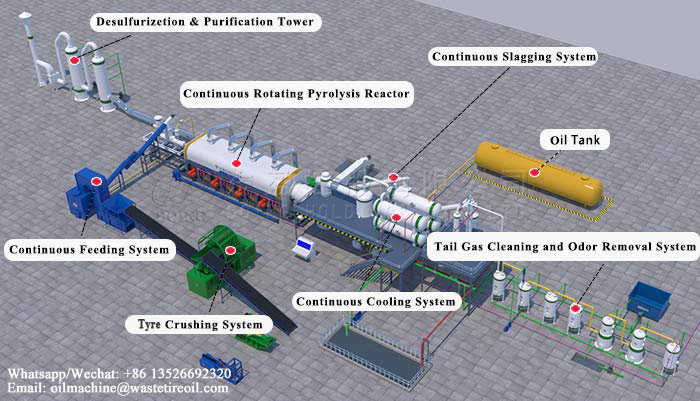

As you can see from the video, continuous waste tyre pyrolysis plant is composed of control cabinet, pyrolysis reactor, the cooling system, tail gas cleaning and odor removal system, smoke cleaning system, carbon black discharge device and safety device.In addition to the appearance and components of the plant we can see from the video, some customers may want to know the operation process of the continuous waste tyre pyrolysis plant. Now I will introduce the running process.

The display of continuous waste tyre pyrolysis plant

The display of continuous waste tyre pyrolysis plant

First, send the tyres with the steel wire removed into the pyrolysis reactor and heat the reactor with fuel;

Second, after the pyrolysis reactor is heated to a certain temperature, oil gas will be generated, then the oil gas goes through the three-step cooling system to be cooled down to oil and enters the oil tank.

Third, during the condensation process, part of the non-condensable gas can be recycled to heat the pyrolysis reactor after being treated by the tail gas cleaning and odor removal system;

Four,the smoke generated by fuel burning can be discharged after being treated by the smoke cleaning system;

Five, after the pyrolysis reaction, the carbon black in the pyrolysis reactor can be collected by the screw conveyor;

The components of continuous waste tyre pyrolysis plant

The components of continuous waste tyre pyrolysis plant

The above is the video of the running process of the continuous waste tyre pyrolysis plant. In addition, Doing Group can also provide 3D animation videos and customer project case videos for those who are interested in the continuous waste tyre pyrolysis plant for reference. If you want to purchase the continuous waste tyre pyrolysis plant, you can contact us at any time, our engineers will give you the suitable solutions. Welcome to consult.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.