Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

Recycled waste engine oil into diesel oil

Engine oil into diesel oil applied for waste engine recycler, waste oil collect center and also used by who have lots of...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste oil distillation machine

Waste oil distillation machine

1. Safety devices such as alarming device, pressure gauge, safety valve. If there is some pressure in the reactor, the alarming device will ring and even no workers hear it, it does not matter as we have the reducing pressure device automatically.

2. Vacuum system can ensure the plant running in a safety condition. Make the whole refining processing be on a normal pressure to avoid accident.

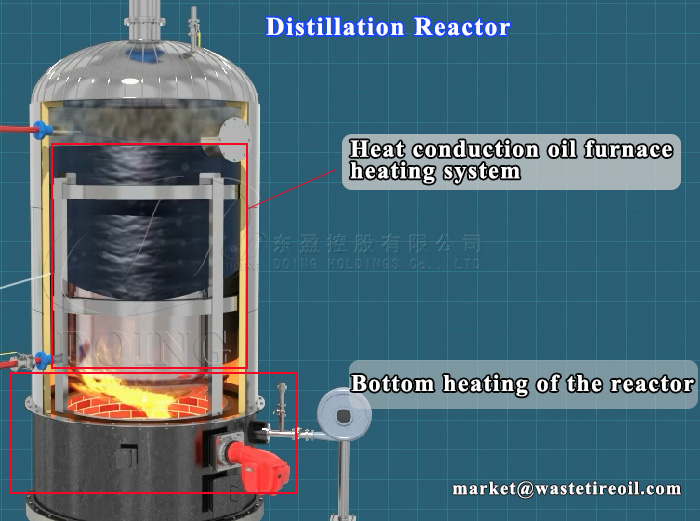

3. Double heating system,this is circulating heating medium combined with fuel heating ystem for distillation, this way, it can not only could save heating fuel, but also could speed up the distillation process, thus to save to time.

4. Our waste oil distillation machine is equipped with diesel further purification system, which can further refine diesel to get light yellow color.

Double heating system

Double heating system

- Features:

- Technical Data:

- Application:

| Technical parameter of recycled waste engine oil into diesel oil | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

Different capacity of waste oil distillation machine

Different capacity of waste oil distillation machine

Recycled waste engine oil into diesel oilapplied for waste engine recycler, waste oil collect center and also used by who have lots of waste tyres and plastic. The final diesel after refining can be used for tractors, trucks, ships and diesel oil generators etc. below is the different waste oil with its oil rate.

Application of refined diesel

Application of refined diesel

| Oil yield of different material: | ||

| No. | Name | Oil yield |

| 1 | Used oil | 85%-90% |

| 2 | Waste plastic oil | 95% |

| 3 | Waste engine oil | 85%-90% |

Doing Group can customize waste oil distillation machine with different processing capacity to meet the production needs of different customers. If you want to know more information about waste oil distillation machine, welcome to consult us feel free.

Previous: Waste crude oil to diesel machine

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.