Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

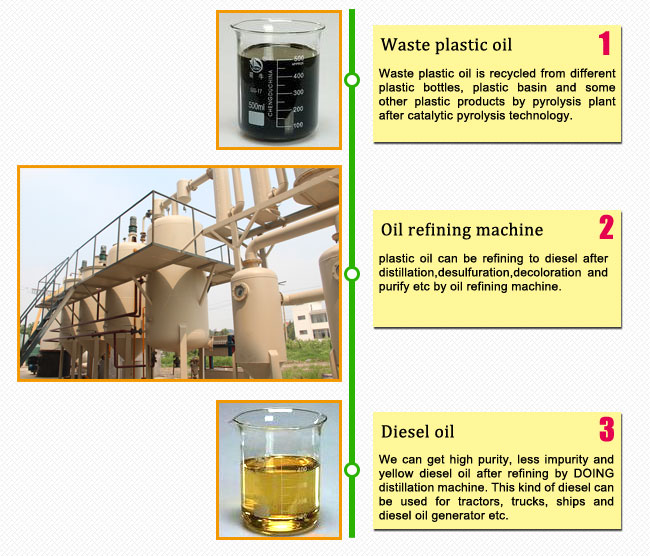

Waste plastic oil to high purify diesel oil

We use green technology (pyrolysis and distillation) to recycle waste plastic to oil resources. We use the pyrolysis te...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste plastic oil to high purify diesel oil

Waste plastic oil to high purify diesel oil

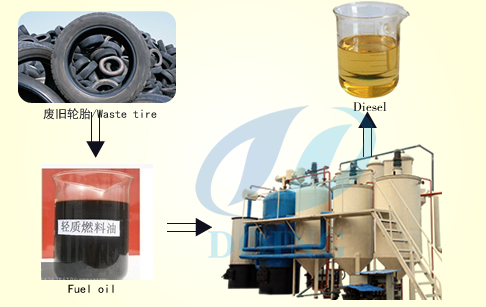

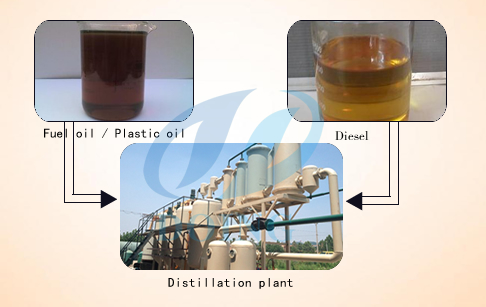

In fact, the plastic to diesel oil is not a step to achieve. We need to use the pyrolysis technology and oil distillation technology. The first step we can get plastic pyrolysis oil by using the waste plastic to oil machine. The second step, with the help of one set of waste plastic to diesel to high pureify diesel oil, the plastic oil can be further refined into diesel fuel.

Waste plastic oil to high purify diesel oil

Waste plastic oil to high purify diesel oil

We use green technology (pyrolysis and distillation) to recycle waste plastic to oil resources. We use the pyrolysis technology to get fuel oil from waste plastic, and then refine the Waste plastic oil to high purify diesel oil technology, which could better solve the oil resources decreasing problem while disposing of the waste.

Waste plastic oil to high purify diesel oil advantqage

Waste plastic oil to high purify diesel oil installtion in Mexico

Waste plastic oil to high purify diesel oil installtion in Mexico

Safe:

1. Hydroseal and vacuum system will prevent exhaust gas from going back to condensers and reactor.

2. Equipped with thermometer, pressure gauge, safety value and electric control system, the machine can avoid danger in the production process.

Environmental Protection:

1. In the dedusting system, three steps are used to dedust the hot smoke from reactor, which ensures the released gas is pollution-free.

2. The exhaust gas will be directly recycled for heating reactor, no gas pollution.

3. All parts are well-sealed, so air leakage can be avoided.

- Features:

- Technical Data:

- Application:

| Technical parameter of waste plastic oil to high purify diesel oil | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

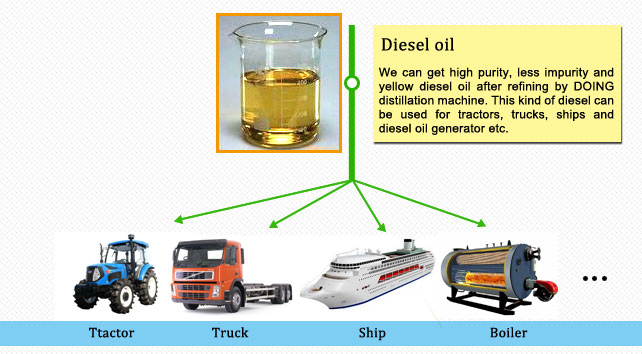

The diesel fuel obtained can be widely used in more kinds of diesel engines and will produce less smoke and less noise than regular diesel fuel. In addition to producing products that have high economic values, our plants also have the features of safe, energy saving and environment friendly

Diesel application

Diesel application

Previous: Tire oil to diesel refining plant

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.