Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

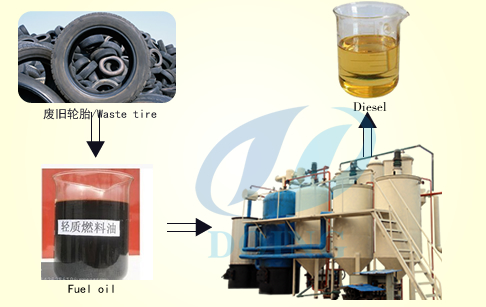

Waste oil to diesel refinery plant

Here we mainly introduce our waste oil to diesel refinery plant, taking the 5D/T waste oil to diesel refinery plant as e...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Waste oil to diesel refinery plant

Waste oil to diesel refinery plant

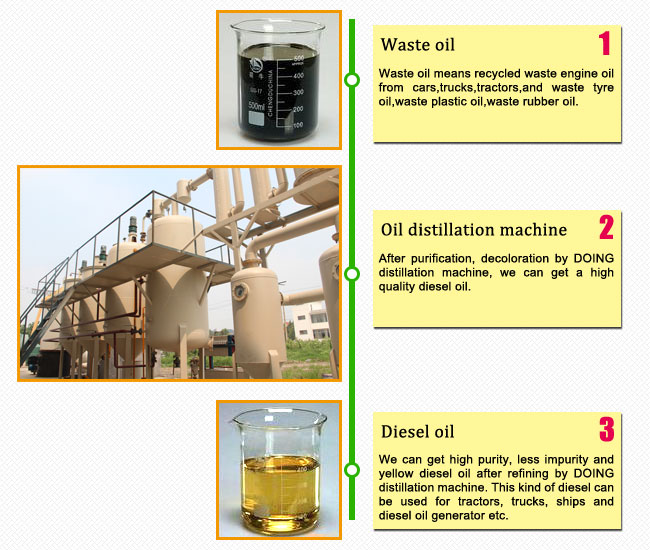

DOING 5T/D waste oil to diesel refinery plant is mainly composed of 4 reactors, cooling system, vacuum system, filtering system and de-dusting system. Our waste oil to diesel refinery plantcan refine waste tire oil into diesel very efficiently, and at the moment it is the most energy-saving refinery equipment in the market.

Doing waste oil to diesel refinery plant have below characteristics:

1. After 2 years’ research and development, our distillation technology is already mature.

2. Can refine 3 kinds of oil--waste tire oil, plastic oil and waste motor oil.

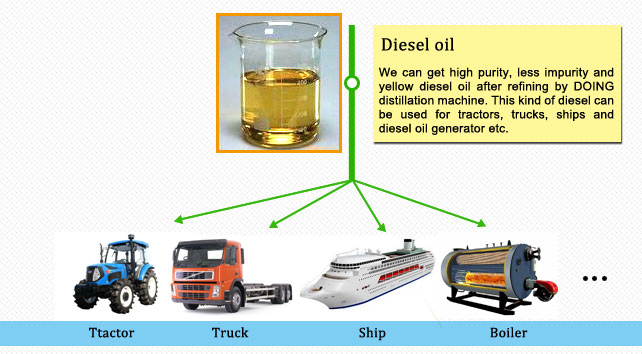

3. The final oil can be directly used for diesel oil generator, trucks and vans, etc.

4. Indirect heating by boiler heating system can greatly increase the service life of our waste oil to diesel plant distillation plant.

5. Three steps purifying process ensure final diesel pure and high quality

- Features:

- Technical Data:

- Application:

| Technical parameter of waste oil to diesel refinery plant | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | motor oil, waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |

- Features:

- Technical Data:

- Application:

Diesel application

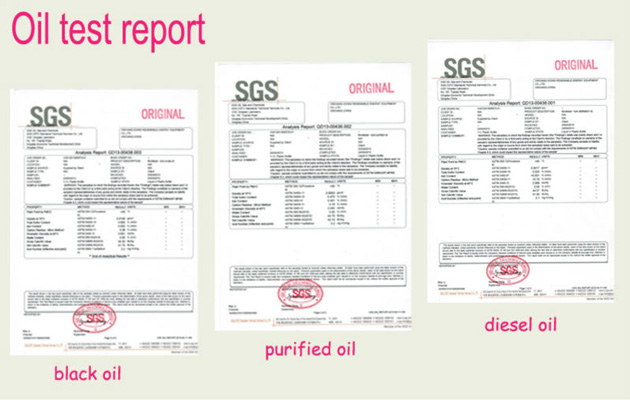

Oil test report

Previous: Waste plastic oil to high purify diesel oil

Next: Nothing

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.