High capacity plant convert waste plastic to oil

DOING waste plastic to oil plant can recycling of different plastics size, for both industrial and home uses, can easily transform a kilogram of plastic waste into a liter of oil with plastic pyrolysis process. Waste pyrolysis of plastic to oil plant uses a high temperature controlling electric heater instead of flames, pyrolysis processing anything from polyethylene or polystyrene to polypropylene.

The automatic industrial automatic convert waste plastic to oil plant manufactures which utilizes advanced technique and equipment and owns reasonable technique and plastic pyrolysis plant design can do plastic waste disposal split into liquid fuel oil (after fractionation adjustment will get high quality automotive fuel) and minimum incondensable gas through pyrolytic reaction. The design of pyrolysis of plastic waste machine the whole technique is very reasonable and the whole production procession takes places in close condition and thus eliminating the environment pollution, realizing energy recycling and achieving admirable environmental, social and economic benefit.

|

Technical parameter of high capacity plant convert waste plastic to oil |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyre/plastic |

Waste tyre/plastic |

Waste tyre/plastic |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

6 ton |

8 ton |

10 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about high capacity plant convert waste plastic to oil |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

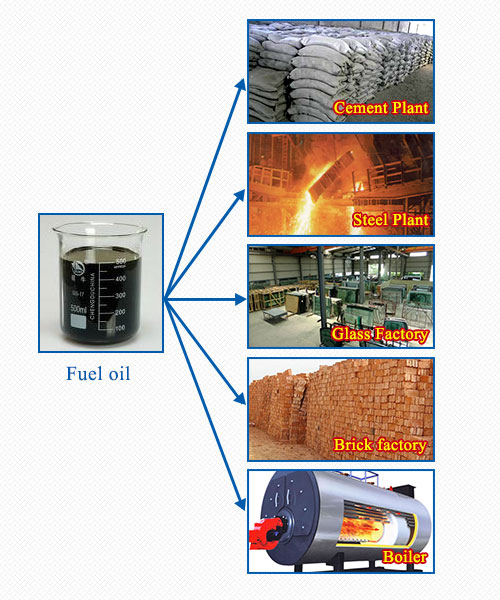

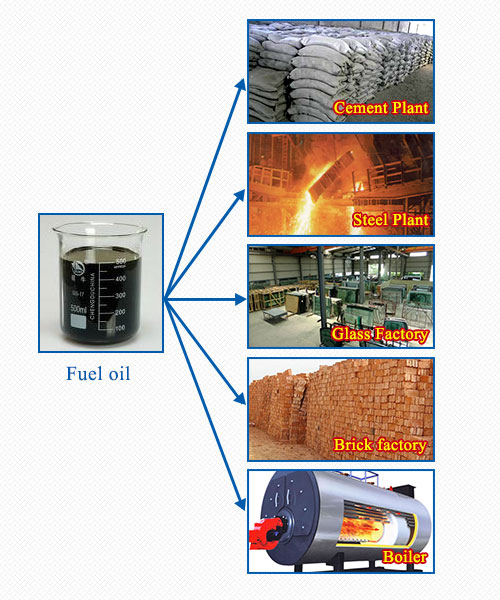

Usage of plastic oil

DOING waste plastic to oil plant with characters of high automatic degree, high production efficiency, excellent safety performance, environmental performance, social benefit and economic benefit can be widely applied in the industrial production.