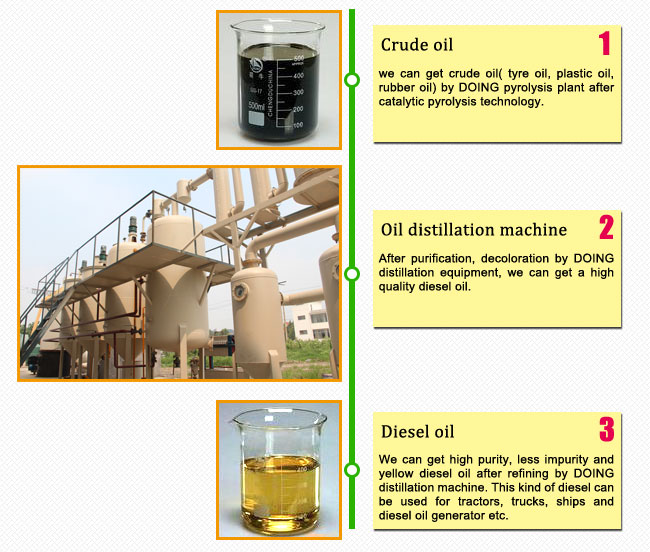

Crude oil to diesel distillation machine process: 1. Pump the waste oil into reactor by oil pump. 2. Use coal/wood/natural gas/fuel oil/electricity heating the reactor. 3. After heating some time, the liquid oil will become oil gas, oil gas will be liquefied by the cooling pipe and condensers then will go into oil tank. Here we get mixed oil, or u can also call it fuel oil. If you wanna get a different quality diesel separately, through temperature control could separate it and collected into two different oil tanks.

| Technical parameter of crude oil to diesel distillation machine | |

| Items | Contents |

| Model | DY-5t, DY-10t, DY-20t, DY-50t… |

| Raw material | waste tire crude oil, plastic crude oil |

| Structure form | Vertical (easy cleaning and maintenance) |

| Heating method | Indirect heating to prolong the machine service life |

| Operating pressure | Constant pressure |

| Heating material | Coal, charcoal, fuel gas, fuel oil |

| Average out-put oil rate | 95% |

| Material of reactor | 4 reactor with different material |

| Thickness of reactor | 18mm |

| Mode of cooling | Recycled water cooling |

| Power in total | 20 Kw |

| Service life | average 7 years |

| Land area | 180㎡ |