Product

Project Case

-

-

DOING Three 15-ton Batch Tire Pyrolysis Units in Myanmar On-site Installation Experience

-

India 50TPD Fully continuous rubber pyrolysis machine installed

-

DOING 15 TPD semi-continuous tire pyrolysis equipment installed in Indonesia

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

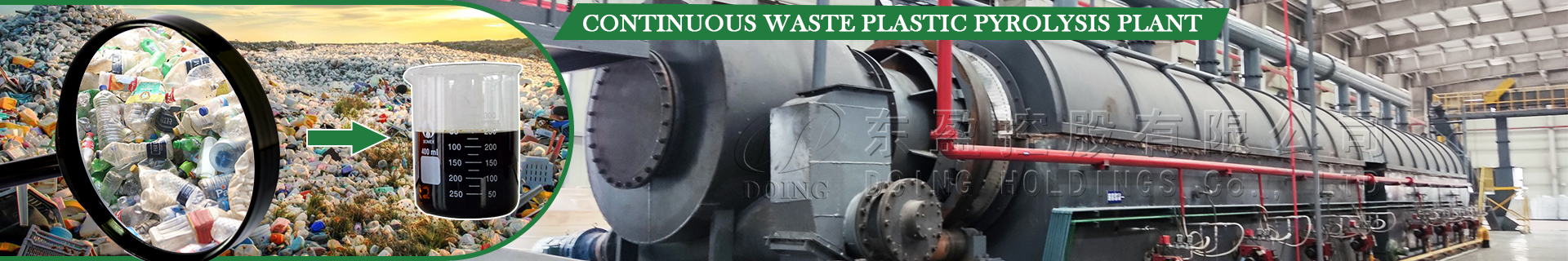

Continuously convert waste plastic to fuel oil pyrolysis plant

Continuously convert waste plastics into fuel oil pyrolysis plant is the latest cracking equipment developed by DoingGro...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

DoingGroup's continuous plastic pyrolysis plant

Plastic continuous pyrolysis plant is the latest equipment developed by DoingGroup for large and medium-sized refineries and workshops. Its purpose is to meet large-scale refinery demand. The same working principle as the pyrolysis plant, the difference is that it uses a PLC control system, a high degree of automation, saving manpower; In addition, the Plastic continuous pyrolysis plant truly realized 24 hours of continuous work, continuous feed on one side, continuous slag on one side . Continuous pyrolysis plant can not only handle waste plastics, but also can handle waste tires, waste rubber and all other solid organic materials that can be cracked.

The plastic continuous pyrolysis plant of DoingGroup mainly includes feeding system, unloading system, pyrolysis reactor, oil and gas filter, spray cooling system, oil and gas recovery system, and central electric control system. And the plant is also equipped with a large heat exchange area tube condensing device, which can effectively improve the cooling efficiency and product output rate.

Plastic continuous pyrolysis plant working process

Plastic continuous pyrolysis plant working process:

1. Collect waste plastics and work with your local waste recycling station.

2. Place the collected plastic waste into a plastic crusher and break the waste plastic into pieces for use.

3. The broken waste plastic was continuously thrown into the continuous pyrolysis plant and the reactor was heated.

4. Through a multi-stage heating system, waste plastics crack oil and gas.

5. The cracked oil and gas enters the condensing system under the action of high and low pressure, is liquefied into heavy oil, and falls into the oil tank.

6. The carbon black produced during the combustion process will be automatically discharged by the system.

7. Desulfurization of the obtained heavy oil is the final fuel oil.

DoingGroup's continuous pyrolysis plant

The main advantages of DoingGroup's plastic continuous pyrolysis plant:

1. The use of PLC control system, a high degree of automation, does not require a lot of manpower, saving expenses.

2. It can work continuously for 24 hours, continuous feed on one side and continuous slag discharge on one side. Save time and improve equipment operation efficiency.

3. Single machine processing capacity, small footprint.

4. Accurately calculate the system to ensure full cracking and improve oil yield.

5. Indirect heating, long equipment life.

- Features:

- Technical Data:

- Application:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

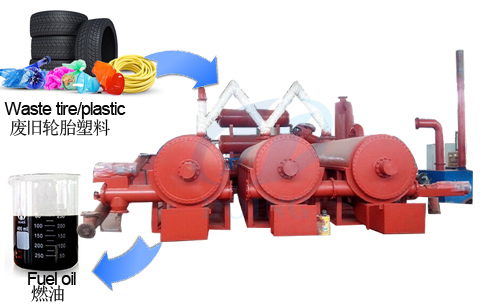

| 11 | Feedstock | Waste tire/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

1. Fuel oil: Mainly used in steel plants, boiler heating, heavy oil generators, and cement plants.

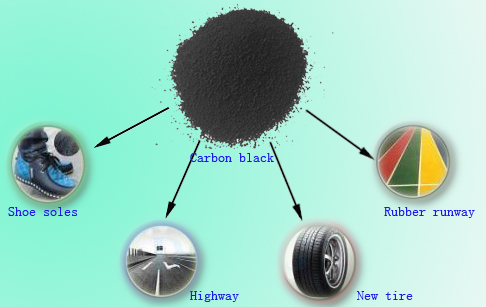

Carbon black usage

2. Carbon black: It is mainly used for pressure ball combustion and refined milling. Refined flour can be used for new tires, rubber soles, and pigments.

3. Combustible gas: It will be recycled by the equipment and used for the heating fuel of the reactor.

The pyrolysis product rate of all kinds of waste tires, rubber, plastic material.

Item fuel oil steel wire carbon black combustible gas

tires/truck tires 45%-50% 15%-20% 30% 5%-10%

car tires 40-45% 10%-15% 40% 5%-10%

motorbike bike tires 30%-35% 5%-10% 10% 5%-10%

rubber/cable 25%-35%

shoe sole 25%-35%

mixed shoe sole 20%-30%

slipper 20%-30%

waste fiber carpet 30%

PMMA 40%

other mixed rubber 35%

waste plastic PE 85%-95%

PP 80%-90%

PS 80%-90%

ABS 40%

pure white plastic 60%-70%

fishing net, safety net 45%-50%

MAMEI 40%

plastic brand 20%

pulp 20%-30%

daily life rubbish 30%-50%

pure plastic cable 60%-80%

pure purchase bag 50%

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.