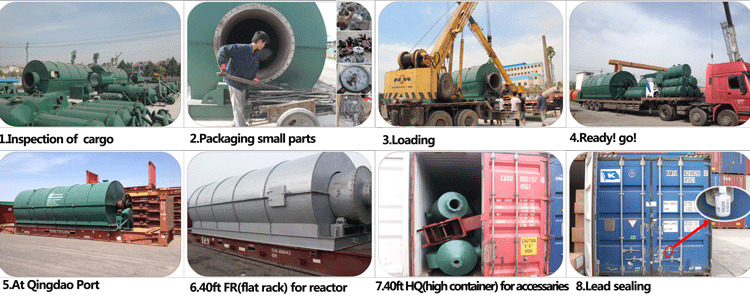

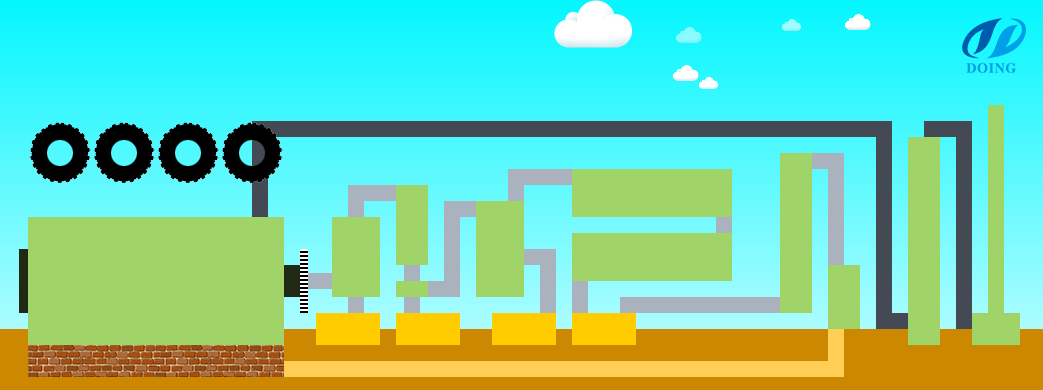

DOING GROUP is leading supplier of the industry to provide Waste plastic to oil plant Imported using latest and advance technology machines. Provided in various specifications to cater to the diverse customer demands, these is provide 10 ton and 5 ton plant per day production plants are widely applauded due to their huge production capacity and low maintenance. We are also acknowledged for providing designing and services of these plants.