Product

Project Case

-

DOING 15TPD semi-continuous pyrolysis plant was installed in Brazil

-

1TPD Waste Oil to Diesel Refinery Machine Operation Site in Thailand

-

Transforming Paper Mill Plastic Waste into Diesel Plant Installed in Mexico

-

-

-

DOING Waste tyre to diesel recycling plants were successfully installed in Japan

-

Waste tire to diesel recycling plant was put into operation in South Africa

-

14MTPD Capacity of Waste oil recycling refinery plant project in Ghana

-

Continuous rubber tyre pyrolysis machine installed in Liaoning,China

-

50TPD fully continuous waste tyre pyrolysis plant installed in Russia

FAQ

-

Continuous Pyrolysis plant

-

Oil Refining Machine

-

Auxiliary Equipment

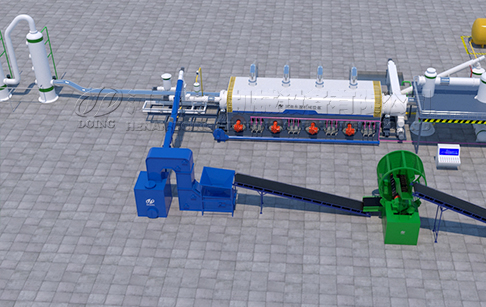

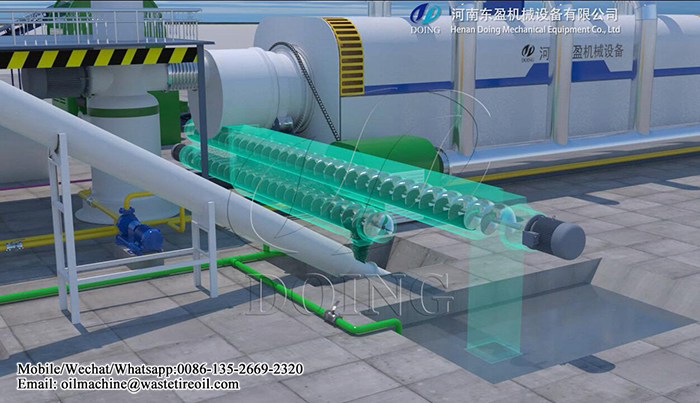

Fully automatic waste tyre pyrolysis plant

Fully automatic waste tyre pyrolysis plant can convert waste tyre to fuel oil, carbon black and steel wire. Due to more ...

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail: market@doingmachinery.com

E-mail: market@doingmachinery.com

- Features:

- Technical Data:

- Application:

Fully automatic waste tyre pyrolysis plant can convert waste tyre to fuel oil, carbon black and steel wire. Due to more environment-friendly and human-friendly than the batch waste tyre pyrolysis plant, fully automatic waste tyre pyrolysis plant is welcomed by more and more people in many countries. Here I will list its main features for your better understanding.

DOING fully automatic tyre pyrolysis plant

DOING fully automatic tyre pyrolysis plant

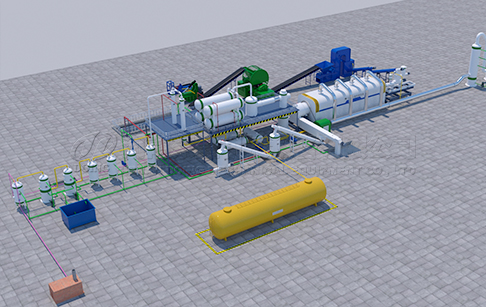

Security:

The equipment adopts auto-welding technology and all of the welding will be detected by our professional welders in factory who are skilled in the auto-welding to ensure the welding quality and the welding shape. We have process controlling system for the quality, every manufacture process, manufacture date, etc. Furthermore, our fully automatic waste tyre pyrolysis plant is equipped with safety valves, emergency valves, pressure and temperature meters, as well as the alarming system to ensure the safety of operation.

Environmental-friendly:

To some extent, the fully automatic waste tyre pyrolysis plant is 100% pollution-free, because the whole process of fully automatic tyre pyrolysis plant from raw material feeding to the final tyre pyrolysis carbon black discharging is operated in a completely sealed environment, and the excess syn-gas can be 100% used for heating the pyrolysis reactor, no waste and no release. Besides, the tyre pyrolysis carbon black can be directly collected with ton bags, no black powders flying to make factory dirty.

Sealed carbon black discharging system for environmental protection

Sealed carbon black discharging system for environmental protection

Easy Maintenance:

We supply detailed operation & maintenance manual to well guide our customer to do the operation and maintenance work. Before this, our engineer will do the “technology -transfer” on the customers' spot, training them till they learned how to correctly operate the machine and do the maintenance.

High profit:

Answer: Our fully automatic tyre pyrolysis plant can be continuous running for one month or even longer time if no emergency happens. And before the stop, the machine just needs to be fueled one time. Take our 50tpd automatic tyre pyrolysis plant for example, it only needs about 900kg diesel to start up and then does not consume more fuel before the machine stop running. Besides, since it is fully automatic, so it is very labor-saving, 2-3 workers are enough to take care of the plant. So it is more profitable than the batch tyre pyrolysis plant. Related reading: the difference of batch and continuous waste tyre pyrolysis plant ]

- Features:

- Technical Data:

- Application:

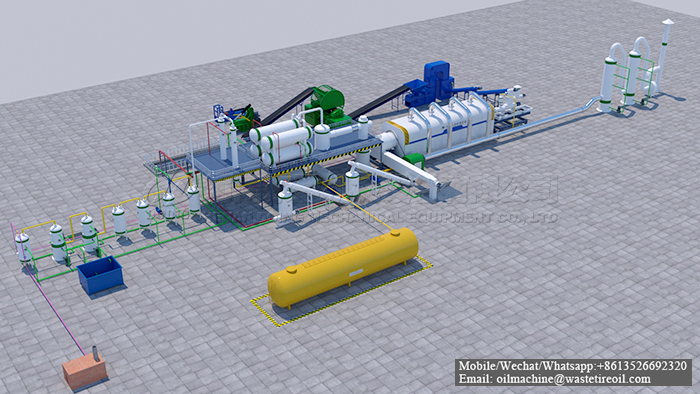

The technical parameters of fully automatic waste tyre pyrolysis plant:

| No. | Item | Specifications | ||||||

| 1 | Model | DY-C-10 | DY-C-20 | DY-C-30 | DY-C-50 | DY-C-60 | DY-C-80 | DY-C-100 |

| 2 | Cpacity | 10T/D | 20T/D | 30T/D | 50T/D | 60T/D | 80T/D | 100T/D |

| 3 | Power | 35Kw | 50Kw | 65Kw | 80Kw | 90Kw | 105Kw | 120Kw |

| 4 | Working type | Continuous | ||||||

| 5 | Reactor deisgn | Mutiple reactors (The quantity and size depends on the raw material condition) | ||||||

| 6 | Rotating | Internal rotating | ||||||

| 7 | Cooling system | Recycled waster cooling | ||||||

| 8 | Reactor material | Q245R/Q345R boiler plate | ||||||

| 9 | Heating method | Indireact hot air heating | ||||||

| 10 | Heating fuel | Fuel oil/gas | ||||||

| 11 | Feedstock | Waste tyre/plastic/rubber | ||||||

| 12 | Output | Fuel oil, carbon black | ||||||

- Features:

- Technical Data:

- Application:

The end product of fully automatic waste tyre pyrolysis plant

Fuel oil

Fuel oil made from waste tyre by fully automatic waste tyre pyrolysis plant

Fuel oil made from waste tyre by fully automatic waste tyre pyrolysis plant

Fuel oil from waste tyre are used in below industries:

A.power plant factory

B.glass factory

C.cement factory

D.ceramic factory

E.aluminum factory

F.boiler factory

G.central heating factory

H.painting factory

Carbon black

Carbon black made from waste tyre by fully automatic waste tyre pyrolysis plant

Carbon black made from waste tyre by fully automatic waste tyre pyrolysis plant

Carbon black from waste tyre are used in below industries

A.electric cable jacketing

B.conveyor ban

C.hose and doormat

D.black nylon bag

E.rubber additive

F.automatic spare parts

G.heat isolation

H.black colorant in rubber materials

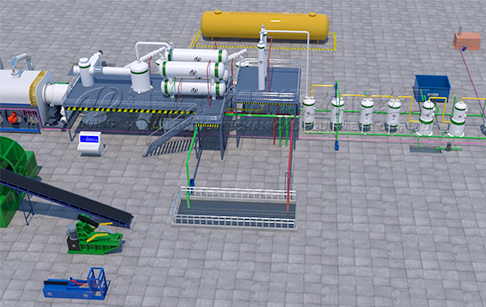

Fully automatic tyre pyrolysis plant project site

Fully automatic tyre pyrolysis plant project site

As one of the most professional fully automatic tyre pyrolysis plant manufacturer, DOING has devoted a lot of efforts in research and design. We promise a perfect after-sale service for every customer of us. You can even choose a turn-key project if you don't have enough time to set up this kind of machine by yourself. The industry of waste to energy is now developing fast and gaining more and more official support of the governments of every country in the world, therefore, it will be a big chance for everyone who wants to invest in it. Now leave your message here directly for more information about fully automatic tyre pyrolysis plant if you're interested in.

Leave A Message

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.