Contact Us

-

Cell/WhatsApp: +86-135-2669-2320

Cell/WhatsApp: +86-135-2669-2320

-

Phone: +86-371-56771821

Phone: +86-371-56771821

-

E-mail:

market@doingmachinery.com

E-mail:

market@doingmachinery.com

Product

Project Case

-

Waste tire/tyre recycling pyrolysis machine project in Panama

-

Waste tyre to fuel oil pyrolysis plant project in Bangladesh

-

12T oil sludge treatment pyrolysis plant sent to Luoyang, China

-

-

Waste plastic to oil pyrolysis plant successfully installed in India

-

The latest continuous process tyre pyrolysis plant installed in Mexico and reported by local news

-

10T continuous waste plastic pyrolysis plant installed in Monterrey, Mexico

-

Italy customer set up successfully waste plastic to fuel oil pyrolysis plant

-

-

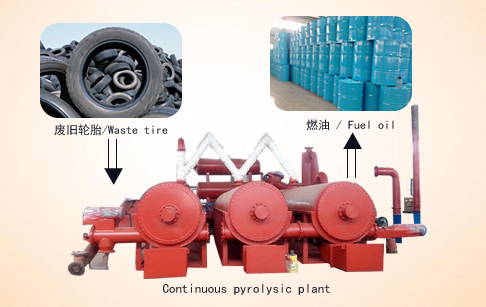

Fully continuous tyre pyrolysis plant

With more than ten years of experience and efforts,Doing produced fully continuous tyre pyr...

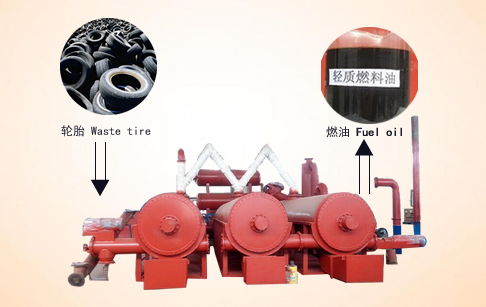

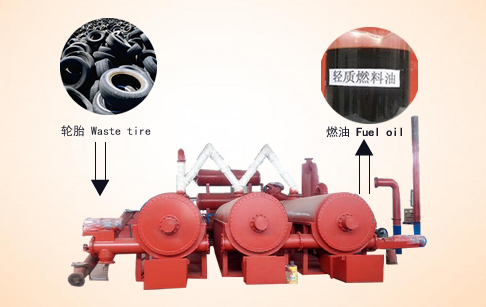

Continuous waste tyre pyrolysis plant

More and more waste tyres not only take up the farmland but also become a breeding ground ...

Continuous waste tire rubber plastics pyrolysis plant

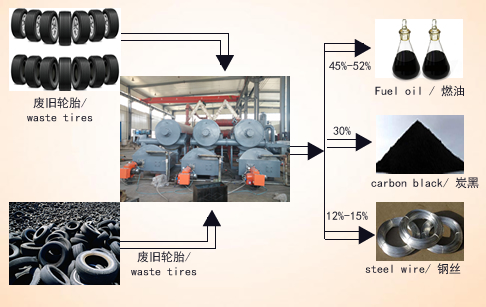

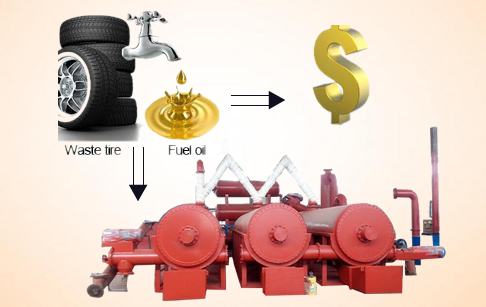

The best method is using the pyrolysis technology to change the waste tire/plastic into the...

Continuous scale tire pyrolysis unit

For continuous scale tire pyrolysis unit main raw material is waste tire/tyre.which can be ...

Automatic continuous waste tyre pyrolysis plant

This automatic continuous waste tyre pyrolysis plant uses the most advanced pyrolysis techn...

Waste tire pyrolysis continuous machine

this kind of batch type waste tire pyrolysis continuous machine may not meet their demand....

High technology fully continuous waste tire pyrolysis plant

Through the use of fully continuous waste tire pyrolysis plant manufactured by Doing compan...

Continuous tyre pyrolysis system

The continuous tyre pyrolysis system is equipped with automatic feeding and discharging sys...

Continuous type tyre pyrolysis plant

Continuous type tyre pyrolysis plant adopted advanced technique and machine design can spli...

Automatic and continuous waste tire pyrolysis plant

Automatic and continuous waste tire pyrolysis plant is very popular in recent days, it can ...

Fully automatic continuous waste tire pyrolysis plant

Now our continuous waste tire pyrolysis plant is ready and has accessed to the internationa...