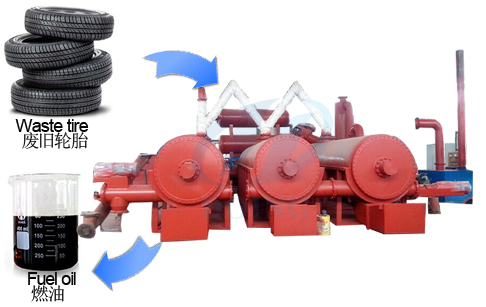

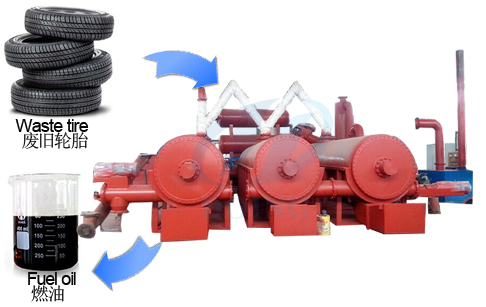

Continuous waste tyre pyrolysis plant

Continuous waste tyre pyrolysis plant

With the development of automobile industry, tyre demand is increasing day by day. According to statistics, 50%-55% raw rubber are used for tyre manufacture every year. However, waste tyre pollution problem exists in each countries. More and more waste tyres not only take up the farmland but also become a breeding ground for diseases, which causes pollution and threaten people’s life.Henan Doing produced continuous waste tyre pyrolysis plant can solve the problem.

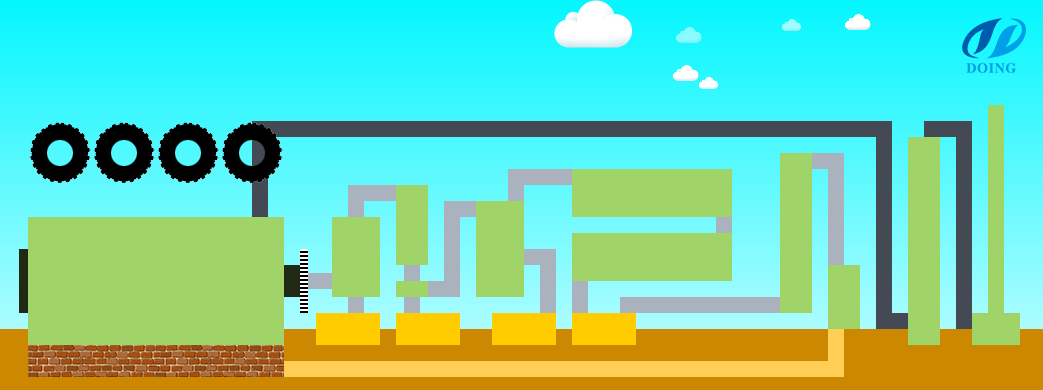

Continuous waste tyre pyrolysis plant advantage

Firstly, zero emission. In the dedusting system, three steps are used to dedust the hot smoke from reactor, more than 95% of the dust would be removed. The released gas is pollution-free and can be discharged in the air directly.

Secondly, high efficiency. We adopt new type of condensers which can further ensure and improve the oil yield efficiency. The catalyst is made from 24 chemicals, which not only reduces sulfur content and density of oil, but also improves its flavor and color.

Continuous waste tyre pyrolysis plant technical data

|

Technical parameter of continuous waste tyre pyrolysis plant |

|

No. |

Items |

Contents |

|

1 |

Equipment type |

DY-1-6 |

DY-1-8 |

DY-1-10 |

|

2 |

Raw material |

Waste tyres |

Waste tyres |

Waste yres |

|

3 |

Structural form |

Horizontal rotation |

Horizontal rotation |

Horizontal rotation |

|

4 |

24-hour Capacity |

10 ton |

20 ton |

30 ton |

|

5 |

Oil yield |

2.7-3.3ton |

3.6 -4.4ton |

4.5 -5.5ton |

|

6 |

Operating pressure |

Normal |

Normal |

Normal |

|

7 |

Material of pyrolysis Reactor |

Q245R |

Q245R |

Q245R |

|

8 |

Thickness of pyrolysis Reactor |

16mm |

16mm |

16mm |

|

9 |

Rotate speed of pyrolysis Reactor |

0.4turn/minute |

0.4turn/minute |

0.4turn/minute |

|

10 |

Total power |

19KW |

19KW |

19KW |

|

11 |

Mode of cooling |

Water cooling |

Water cooling |

Water cooling |

|

12 |

Cooling area of condenser |

100sqm |

100sqm |

100sqm |

|

13 |

Kind of transmission |

Internal gear drive |

Internal gear drive |

Internal gear drive |

|

14 |

Noise dB(A) |

≤85 |

≤85 |

≤85 |

|

15 |

Size of Reactor(D×L) |

2200×6000 |

2200×6600 |

2600×6600 |

|

16 |

Working form |

Intermittent operation |

Intermittent operation |

Intermittent operation |

|

17 |

Delivery time |

20days |

20days |

20days |

|

18 |

Weight |

27T |

30T |

35T |

|

Prepared by customer about continuous waste tyre pyrolysis plant |

|

No. |

Item |

Consumption |

|

1 |

Coal(for choice) |

500kg/day |

|

2 |

Wood(for choice) |

800kg/day |

|

3 |

Natural gas(for choice) |

100-150kg/day |

|

4 |

Oil(for choice) |

300-350kg/day |

|

5 |

Electricity |

244kwh/day |

|

6 |

Water(recycled) |

60㎥ /month |

|

7 |

Total power |

19kw |

|

8 |

Land area |

35m*15m |

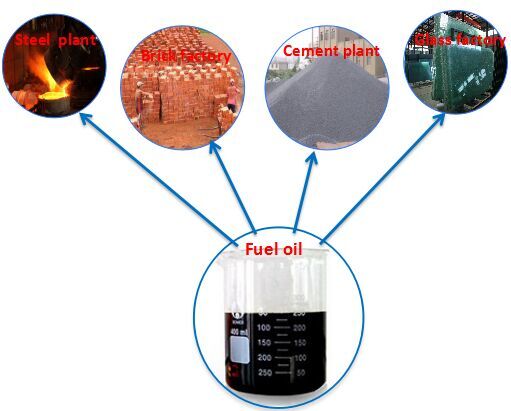

Continuous waste tyre pyrolysis plant final product application

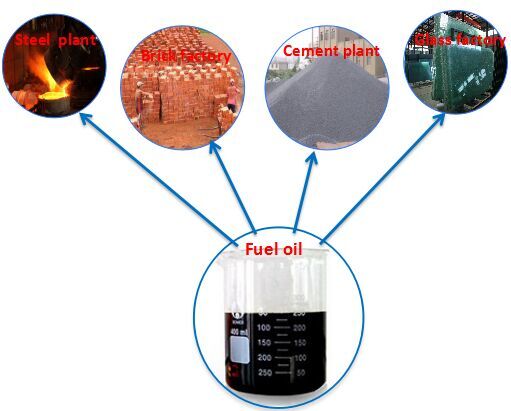

Fuel oil application of continuous waste tyre pyrolysis plant

Fuel Oil (45% to 52%)

The main application of oil products produced by Doing continuous waste tyre pyrolysis plant is the fuel oil that is wide used for industrial and commercial purposes. 45% to 52% oil of the amount of recycled scrap tires can be carried with licensed tanker trucks.

Steel Wire (12% to 15%)

The third product of continuous waste tyre pyrolysis plant is steel wire, the quantity of steel wire is about 12% to 15% according to tyre quality. It is very easy to sell steel wire scrape in local market.

Carbon Black Powder (30%)

The second product of continuous waste tyre pyrolysis plant is carbon black. The quantity of carbon black is about 30% to 35% according to tyre quality. The use of carbon black is as a chemical strengthener in rubber and coloring agent in pigment industries. This carbon black price is very competitive compared to petroleum carbon black, so our pyrolysis carbon black is good option in stead of petroleum carbon black.

Gases (About 10%)

We get about 10% pyrolytic gases during pyrolysis process. The main component of this gases are methane (CH4), so we can not condense and store this gases. We use this gases to heat the reactor and we can use exceed gases for other heating application.