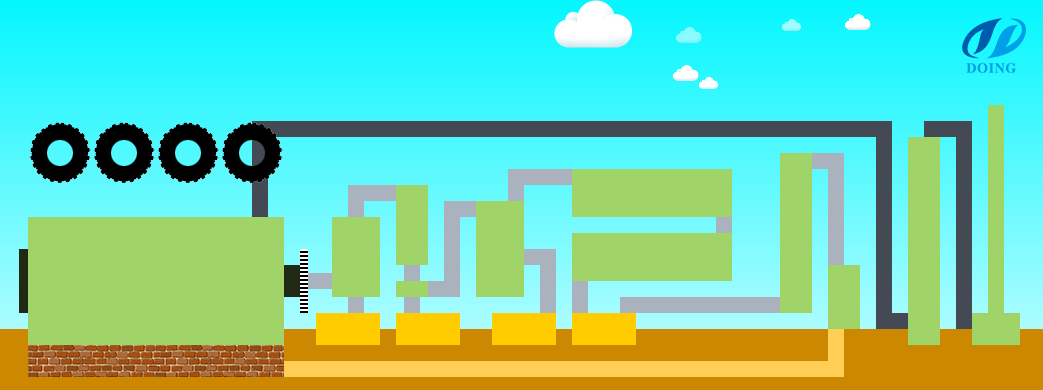

DOING factory manufacture many different modes of waste plastic pyrolysis to oil plant to meet pyrolysis machine buyer needs

Waste plastic pyrolysis to oil plant

DY-6T capacity waste plastic pyrolysis to oil plant (D2200mm*L6000mm)

1. This mode of waste plastic pyrolysis to oil plant can load 6 tons of plastic.

2. After finishing one batch, with auto-feeder, you don't need to wait the pyrolysis machine cooling down since workers will have to go inside to feed material. If you don't have one, in that way it will be time-wasting and dangerous.

3. Built-in spiral plates, these plates will make the waste plastic go ahead.

DY-8T capacity waste plastic pyrolysis to oil plant (D2200mm*L6600mm)

1. It can load 8 tons of waste plastic.

2. The reactor adopts Q245R steel plant and its thickness is 16 mm, which can bear 500-750 batches.

3. We can also make reactor by material Q245R, which obviously prolong service life 3-5 times.

4. The reactor has two layers, the outer layer built-in cotton insulation, fire cement and steel.

DY-10T capacity waste plastic pyrolysis to oil plant (D2600mm*L6600mm)

1. Working with Auto-feeder, it is able to contain 10 tons or 12tons waste plastic.

2. The diameter of feeding port is 1200mm or 1400mm.

After 2 hours feeding time, it's time to heat the reactor by coal/wood/natural gas/crude oil. Generally speaking, when the temperature ups to 155 Celsius degrees around, the oil gas will generate.

Waste plastic working time you may need:

Let’s take 10 tons waste plastic that processed by DOING waste plastic pyrolysis to oil plant as an example:

| Model | Feeding | Processing | Cooling | Discharge | Total |

| 2200*6000 | 1.5hr | 7-8hr | 1.5hr | 1.5hr | 12hr |

| 2200*6600 | 1.5hr | 8hr | 1.5-2hr | 1.5hr | 14hr |

| 2600*6600 | 2 hr | 10 hr | 2-3 hr | 2-3 hr | 16-18 hr |

| Technical parameter of 6/8/10T capacity waste plastic pyrolysis to oil plant | ||||

| No. | Items | Contents | ||

| 1 | Equipment type | DY-1-6 | DY-1-8 | DY-1-10 |

| 2 | Raw material | Waste plastic | Waste plastic | Waste plastic |

| 3 | Structural form | Horizontal rotation | Horizontal rotation | Horizontal rotation |

| 4 | 24-hour Capacity | 6 ton | 8 ton | 10 ton |

| 5 | Oil yield | 2.7-3.3ton | 3.6 -4.4ton | 4.5 -5.5ton |

| 6 | Operating pressure | Normal | Normal | Normal |

| 7 | Material of pyrolysis Reactor | Q245R | Q245R | Q245R |

| 8 | Thickness of pyrolysis Reactor | 16mm | 16mm | 16mm |

| 9 | Rotate speed of pyrolysis Reactor | 0.4turn/minute | 0.4turn/minute | 0.4turn/minute |

| 10 | Total power | 19KW | 19KW | 19KW |

| 11 | Mode of cooling | Water cooling | Water cooling | Water cooling |

| 12 | Cooling area of condenser | 100sqm | 100sqm | 100sqm |

| 13 | Kind of transmission | Internal gear drive | Internal gear drive | Internal gear drive |

| 14 | Noise dB(A) | ≤85 | ≤85 | ≤85 |

| 15 | Size of Reactor(D×L) | 2200×6000 | 2200×6600 | 2600×6600 |

| 16 | Working form | Intermittent operation | Intermittent operation | Intermittent operation |

| 17 | Delivery time | 20days | 20days | 20days |

| 18 | Weight | 27T | 30T | 35T |

| Prepared by customer about 6/8/10T capacity waste plastic pyrolysis to oil plant | ||

| No. | Item | Consumption |

| 1 | Coal(for choice) | 500kg/day |

| 2 | Wood(for choice) | 800kg/day |

| 3 | Natural gas(for choice) | 100-150kg/day |

| 4 | Oil(for choice) | 300-350kg/day |

| 5 | Electricity | 244kwh/day |

| 6 | Water(recycled) | 60㎥ /month |

| 7 | Total power | 19kw |

| 8 | Land area | 35m*15m |